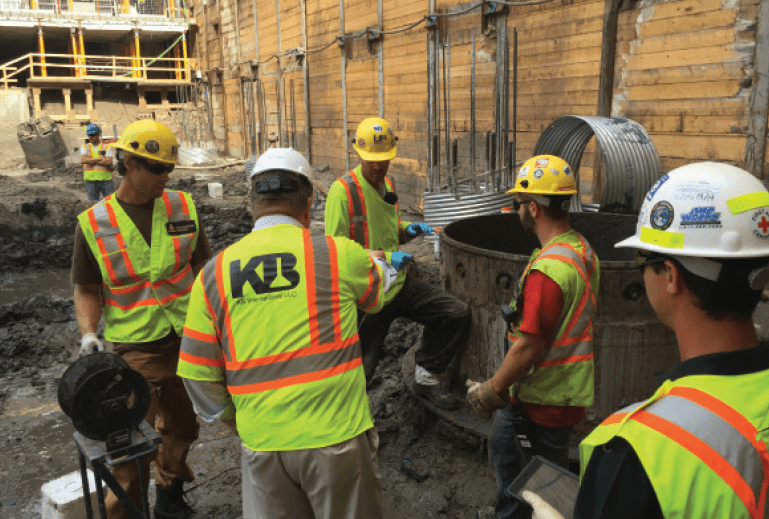

Photo: KB International

For almost 30 years, KB International has been supplying synthetic polymer slurries and stabilization systems to the deep foundation and excavation industries, researching and advancing the technology for successful application in projects around the world.

The slurry displacement method used in drilled shafts first came to North America after the Second World War for use in Texas’s booming oil industry, allowing for previously unachievable depths through the use of positive hydrostatic pressure delivered by specially formulated drilling fluid. It wasn’t until the 1950s that research began to find ways to apply the system to the deep foundation industry using bentonite clay slurries. By the 1970s, engineers were looking at using solutions of water-soluble polymer that would deliver both lower environmental impact and lower construction costs. However, these engineered fluids perform very differently from conventional bentonite slurries, and very little was known about how to use them to the best advantage.

Finding a better solution

This was the situation when KB Technologies, later KB International, came onto the scene, determined to address the gap in research and development in the use of polymer slurries. “We saw a need in this market for a slurry product that simply worked better,” said Ken Goodhue, one of the founders and visionaries for the company.

His son and co-founder, Gifford Goodhue, used his extensive background in chemistry to develop the company’s entire spread of polymer products, today holding four U.S. and several international patents for drilling, coring, tunnel boring and deep excavation fluids. When it comes to polymer slurries, this company brings its many advancements in fluid technology to the success of excavations in a wide range of difficult soil conditions.

“In the years since, we’ve worked around the world, focusing on large bridges, buildings and foundations,” said Ken. “We have experience with drilling in 57 countries through every type of set-up and soil formation imaginable. We do some work with the mining industry as well, but our focus has been the piling industry, as we are a leading supplier to that market.”

“We’re constantly advancing,” said Mark Walters, market manager at KB. “Our primary product, our SlurryPRO CDP, has the same name as it did originally, but its performance has doubled or tripled since we began.

“With our polymers, the biggest advantage is the efficiency with which they can build a membrane on the sidewalls of a drill shaft or bored pile or diaphragm wall. That membrane is what gives hole stability throughout excavation. We have not seen anyone else that can even touch what we can do to a sidewall.”

SlurryPRO CDP is KB’s primary base fluid and viscosifying agent that has been specifically designed to form a synthetic membrane on the sidewalls during excavation of a variety of soil and water conditions. It mixes easily, either directly in the hole or in a mix tank, and is environmentally friendly for simple disposal. This polymer slurry seldom requires additives, but when specific soil formations are anticipated, KB can provide the solution.

Training and teamwork

As Walters said, “Ours is a very simple application. One of the things we realized early on in the development of our polymer slurry was that the people applying this stuff don’t have formal chemical education, and with our products they don’t need it. When it comes to training, we believe teaching is more effective when it’s ‘show me, don’t tell me.’”

While on site, company representatives train field personnel on mixing and testing procedures as well as ensuring the fluids system functions properly. KB also offers Mud Schools that can be performed in a classroom or in the field where the product is being used, along with a curriculum that can be customized to the customer’s specific needs.

During these training sessions, a great deal of time is spent on the environmental aspects of KB’s products. Walters considers this to be one of the company’s biggest initiatives. “We’ve spent an incredible amount of research and time making sure all our products are 100 per cent environmentally friendly, safe for our clients to use and safe for the entire community.

“Customers don’t have to dispose of large quantities and when they do dispose, they can break the polymer back down to water and discharge it into a storm drain, sometimes even getting approval to discharge into rivers. It’s relatively easy to get disposal of the polymer approved once we show how safe it is.”

Walters says another very important consideration is that customers have access to the expertise of the KB team. “We function as more of a partner to our clients by providing onsite service as well as assisting with submittals and offering training.

“That onsite service and partnership really hits home for the piling industry. Our company representatives can be relied upon to make sure the product is functioning, to answer any and all questions from their clients about the polymer. Our field representatives can be contacted for start-ups or for the duration of the entire project. We bring a lot of experience to these projects, another set of eyes that our customers value a great deal.”

Polymer success beneath the Canadian landscape

In 2009, KB International provided drilling support fluid and technical services for construction of the Golden Ears Bridge in Vancouver. Designed to support increased traffic for the Vancouver 2010 Winter Olympics, the six-lane bridge would span the environmentally sensitive Fraser River. Not only did KB demonstrate the nature-friendly characteristics of its polymer drilling fluids, but as a result of the superior skin friction of the polymer system and positive load test results during the test shafts, the lengths of the shafts were decreased from 98 to 76 metres.

Amr Aly, project manager with Aecon Foundations sees polymer increasingly being used in Canada as engineers learn more about its properties and see successful outcomes in projects across the country.

He became familiar with KB International while working with Bauer Canada in Fort McMurray and Edmonton, Alta. He said, “My first time using polymer was in winter in Fort McMurray, Alberta, in 2011. At the time, I was working for another company, and we were asked to explore the use of polymer drilling fluids. None of the crew, myself or my supervisors had any experience with polymer and this had promised to be a difficult pile – 43 metres with a surface casing of maybe 3 metres at the top. Gifford Goodhue, one of KB’s partners, came to Fort McMurray to get us set up. At my request he stayed on to train us on how to use the polymer. The client was quite impressed by how clean the product is and its excellent support for that 40-metre open hole. That was my first exposure.”

Aly again worked with KB International in 2014 in downtown Edmonton. on the construction of Rogers Place – the largest mixed-use sports and entertainment district in Canada, consisting of a modern hockey arena, 67-storey tower and a 600-car underground parkade. For optimum wall support and skin friction, KB supplied its Enhanced SlurryPro CDP System along with full-time onsite representation to monitor the fluid conditions, bring insight to challenging situations and ensure a constant flow of polymer to the two drilling rigs that were operating in unison.

“It was a 2-metre [diameter] 75-metre pile, probably one of the longest ever tried in Canada, and it was very successful,” said Aly. “KB helped us set up and was available throughout the job, troubleshooting with us whenever necessary. We have the highest regard for the whole team and have always had a good experience working with them.”

“That project in Edmonton sparked us back into the Canadian market,” said Walters. “We’ve now been involved in metro projects in both Toronto and Montreal, working with major contractors.”

Work on the 19-km Eglinton LRT line in Toronto started in 2016, and is planned to open in 2022. For that project, Aecon successfully applied the KB polymer system to drilled piles 2 metres in diameter and up to 42 m deep at three LRT stations.

The new REM LRT in Montreal is the biggest construction project undertaken in Quebec in the last 50 years, and once again the KB polymer system demonstrated its value. “Polymer use was fairly new for the province. Aecon submitted a proposal to the client to use polymer,” said Aly. “It was accepted by the client and was used successfully to drill piles for the elevated guideway at the West Island sector – up to 2.4 metres in diameter, 30 metres deep.”

In the past, the use of polymer slurry in piling has not been a common application in the Canadian market, but that is changing as KB International continues to advance the technology of its products and educate the industry in their use. Today, around the globe, including in Canada, key players are now recognizing polymer slurry as a legitimate application. ![]()

-

From Historic Foundations to Modern Marvels

April 18, 2024 -

Canadian Construction Trends for 2024

April 16, 2024 -

Substance Use in the Trades

April 12, 2024 -

Putting Technology to Work in Your Business

April 12, 2024 -

A Matter of Life or Death

April 12, 2024