For 33 years, Almita Piling has been a North American leader in helical pile foundation solutions. Surviving and finding success in the recent downturn of Alberta’s economy, Almita is once again looking to the future and expanding its reach into new markets.

Named after the Blackfoot word for “elk,” Ponoka is a central Alberta town that is the birthplace of Almita Piling, a 33-year-old company that has proudly served its clients as a North American leader in helical pile foundation solutions.

Now privately owned by the Lloyd family, the roots of Almita Piling can be traced back to Adrien Trudeau, a Ponoka public school teacher who taught welding and, in 1986, purchased Mr. Steel, a local fabrication shop and welding supply store. Five years later, the company (now called Almita Piling) began fabricating helical anchors used for securing oil service rigs.

Today, Almita’s primary customers are the larger engineering, procurement and construction firms, and general contractors engaged in the oil and natural gas, transmission and distribution, mining, rail, heavy industrial, commercial and renewable construction sectors. The company will also work directly for project owners on transmission projects and oil sands projects.

Almita also serves an important client segment referred to as its “Installer Network.” These are smaller installers who buy piles and accessories from Almita and then install the piles themselves within their local markets.

“Almita offers complete design through to installation of helical pile foundations and our designs are fully customized to specific soil conditions, loads, customer requirements, and site conditions,” said Bill Baillie, senior vice president and leadership team member at Almita Piling. “We also offer other complimentary services such as survey, civil works, welding, structural steel supply and erection. We are ISO certified to ensure the quality of our products and services, and our fabrication shops and welders are [Canadian Welding Bureau] certified in order to meet the standards required for structural fabrication.”

Equipment and expertise

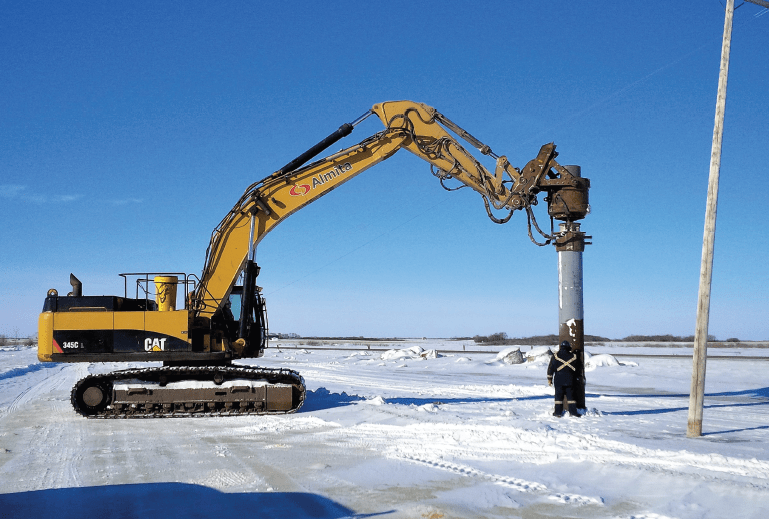

Historically equipped to construct helical pile deep foundations, Almita currently employs more than 20 excavator-based helical piling rigs and has added two driven piling rigs to its fleet. To support pile installation in firmer soils, or in mid-winter frost conditions, Almita also has three drilling units (two truck-based and one excavator-based) that can perform pre-drilling prior to helical pile installation. Almita’s helical piling units are able to install piles up to 40 feet in length and its driven piling units are capable of installing up to 60-foot-long piles. When required, the company is able to add extensions to all of its piles in order to reach deeper embedment depths.

“We also provide helical piles and accessories to installers who have their own installation equipment and may simply need piles and engineering support,” said Baillie. “We stock piles and a variety of capping accessories for immediate purchase, sell drive heads and attachments to those same installers, and even offer rental units as an alternative.”

Almita’s clients have come to rely on the safe and professional execution of its foundation construction projects. One such example is the work done by Almita on Edmonton’s River Valley Mechanized Access project, which provided a funicular and allowed for barrier-free access to the river valley trail systems. The original design for the funicular foundations called for 220 micropiles, ranging from six to 19 metres in depth, but considering the tight project deadlines, the steep slope and the winter construction conditions, the client anticipated that the micropile construction would be difficult and time consuming. Therefore, they approached Almita to provide an alternative helical pile design and, in response, Almita performed static load tests, finalized designs,

fabricated piles and started the installation within a month of being contacted.

“However, the soils proved to be firmer than anticipated due to the extensive excavation for the foundation benches,” said Baillie. “So we quickly adapted the design, performed a production load test to validate the modified design and completed the helical foundations within one month; on schedule and on budget, and saved the City of Edmonton 25 per cent in cost versus the original micropile design.”

Safety is paramount

Almita strives to set itself apart from the competition by its dogged dedication to safety and has the track record to prove it. Almita has worked over 2.5 million labour hours without a single Lost Time Incident; which is a significant achievement for a company of its size. In addition, Almita’s commitment to safety has earned it a Total Recordable Injury Frequency below 1.0 and it has received numerous safety recognitions for its work on major industrial worksites.

“As part of fostering our safety culture, we started instituting the sharing of Safety Moment stories at the start of all meetings,” said Baillie. “The safety story comes from experiences within the company and is tailored to the audience in the meeting. These stories help our employees learn about the safety behaviours Almita is seeking and further personalizes safety.”

Almita’s core values establish the behaviours the company wants from its team members, which, in turn, creates the culture that allows its teams to perform to high standards. Almita’s culture then attracts and retains team members, which allows it to secure the very best talent the industry has to offer.

“With our strong team and culture, we can deliver a truly exceptional customer experience,” said Baillie. “As an industry leader in helical piling, we strive to be easy to work with for our clients and to make them look good. Completing our work safely and on time will mean that our clients have the best start to their project.”

A broad reach, shaping communities

Almita is headquartered in Edmonton, Alta., but the company’s largest facility is back in Ponoka, where it has approximately 28,000 square feet of manufacturing space, 10,000 square feet of heavy equipment maintenance bays and 12,000 square feet of office space. It is here that Almita stages most of its installation fleet and also stocks a significant inventory of pipe that allows it to be able to deliver piles quickly.

The company also maintains facility space in Saskatoon, Sask., and Guelph, Ont.; where it has another 16,000 square feet of manufacturing and office space. Across Canada, Almita manages additional yards for the stocking of smaller piles and accessories for the company’s Installer Network partners. Almita’s U.S. headquarters is based out of Denver, Colo.

Almita strongly believes in giving back to the communities in which it serves and the company has established an annual charitable donation budget to support community-minded initiatives. In 2016, Almita provided and installed piles for a new playground structure at Ponoka Elementary School and also donated space for the relocation of the Ponoka High School welding shop. In addition, Almita employees routinely give their time to various volunteer programs.

Furthermore, Almita strives to work collaboratively with its First Nations partners. The company is a member of the Canadian Council for Aboriginal Business and strongly supports Indigenous entrepreneurship wherever it can. Almita values its Joint Venture Partnership with the Burns Lake Band in north-eastern British Columbia and a number of other First Nations partners. In 2017, Almita provided helical piles and two days of training for Saskatchewan’s Montreal Lake Cree Nation high school, teaching students how to safely operate skid steers and then install the piles to create the foundation for the school’s greenhouse construction project.

“It was a shared experience for both the students and our team to be able to experience each other’s worlds,” said Baillie. “An interesting success occurred on the second day of the training when we had two more students join us because they had heard about the excellent experience from the day-one participants.”

Almita’s Ontario expansion

Just as it did in its early days in Western Canada, Almita believes that in Ontario it will be able to demonstrate that larger diameter helical piles are a viable alternative to the more traditional foundation technologies used for heavier loads. In 2015 Almita began to explore the Ontario marketplace for potential geographic expansion and, a year later, the company successfully acquired Ancora Metalworks, a helical pile manufacturer located in Guelph. This, for the first time, established Almita’s full end-to-end service capability within the province.

“In the Ontario market we see that we can provide that ‘one-stop-shop’ for custom design of the helical pile foundation, fabrication and supply of the piles, and then installation and capping of the piles for the project,” said Jared Harnish, Almita’s regional manager, Ontario. “We have also identified that clients value our ability to custom design and fabricate helical pile solutions to the needs of the specific soils and loads; rather than trying to find a solution using standard, stock parts from a catalogue.”

From Ontario’s Installer Network market, Almita has received feedback that its non-franchise approach is welcomed. Almita will sell piles and accessories directly to the installers, while offering engineering support for the more complex jobs and providing additional training for them to become authorized installers. Almita’s stockpiles are Canadian Construction Materials Centre certified, which offers another guarantee of quality and certainty to its clients.

Some of the hurdles Almita still faces as it finds a home in the Ontario market will be in scaling up resources as it grows; connecting with numerous new clients; understanding differences in labour relations frameworks in Ontario and the Greater Toronto Area; identifying and getting set up on local bid sites and plan rooms; planning for the addition of shop and yard space at the correct strategic time; and also contending with an already tight labour market, which could prove challenging for Almita’s planned growth.

Looking to the future

Almita fully expects to establish a presence within northern British Columbia to further support the region’s major liquefied natural gas projects. By 2020, the company anticipates having operations set up in the lower mainland area of the province. The company also plans to construct additional stockpile yards throughout Canada in order to be closer to and better serve its Installer Network partners.

“A quick response to our client’s needs is critical to their success, as well as ours,” said Baillie. “We take great pride in being able to respond quickly when a client calls for support on a project that is struggling or is a particularly challenging situation. As an industry leader, we believe that if we can ensure our clients look good to their clients, we have done our job.”

Almita’s long-term strategic plan also sees adding other foundation technologies to its table of service offerings and the company has begun to add driven piles, which will expand capabilities in combination with helical piling scopes. Over the next 12 to 18 months Almita expects to be adding further complimentary niche foundation technologies, such as micropiling and grouted helical piles.

-

From Historic Foundations to Modern Marvels

April 18, 2024 -

Canadian Construction Trends for 2024

April 16, 2024 -

Substance Use in the Trades

April 12, 2024 -

Putting Technology to Work in Your Business

April 12, 2024 -

A Matter of Life or Death

April 12, 2024