Compared to many sectors, pile driving has a relatively light impact on the environment.

“For most land-based piling applications, we’re installing untreated steel, concrete or timber, so the environmental challenges are limited,” said Colin Kaufmann, project manager with West Shore Constructors Ltd. of North Vancouver. “But when we’re working with treated or coated materials, or near watercourses, we have a greater potential to impact the environment. While some of our responses to these challenges are prescribed by the regulatory agencies, at other times we must provide our own solutions to those challenges.”

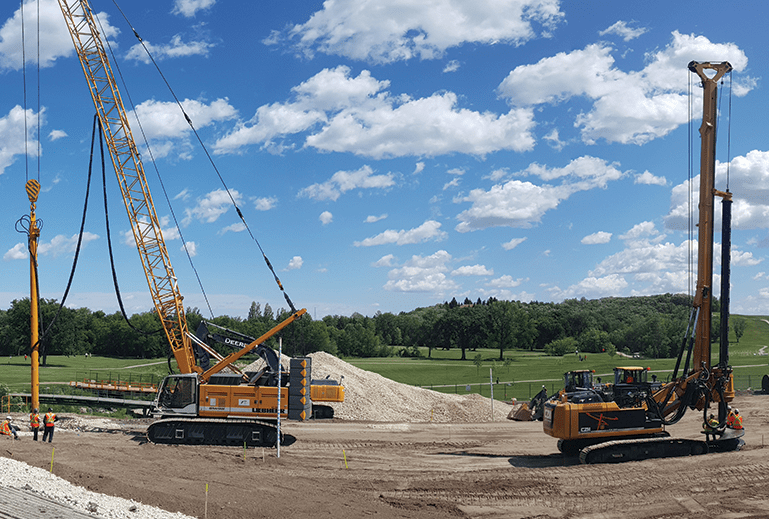

Consider the $1.8-billion Northeast Anthony Henday Drive project, a joint venture currently underway in Alberta between Flatiron Constructors Canada Limited, Dragados, Aecon and LaFarge. It involves 47 new bridges on 18 kilometres of reconstructed six- and eight-lane divided freeway to complete the Edmonton Ring Road.

“We had to build two cofferdams into the North Saskatchewan River, remaining aware of the aquatic sensitivities of resident and migrating wildlife, and of course it’s a major water source for cities downstream,” said project safety manager Garry Hodge of Flatiron Constructors. “Every pickup truck in the fleet has a spill kit, and we used several hundred rig mats to run our cranes into location. When we were at the river, there was limited access to the cofferdam, so guys would park their personal vehicles around 200 metres from the river, even if it was 20 below and they had things to carry,” he said. “The biggest thing is to make sure you establish enough lead time [to plan to meet environmental requirements].”

The environmental management plan

When operating in an environmentally sensitive area, an environmental management plan (EMP) will likely be required, especially if the work takes place near a watercourse. For a recent major sewer project, West Shore Constructors Ltd. was required to create a 30-foot deep trench with sheet piles. At one location, the trench crossed a creek, so the creek water had to be transported across the trench through a steel pipe, and later restored. The dewatering of the trench and the discharge of groundwater required an erosion and sediment control plan. These plans were only part of the project EMP.

All in a day’s work for most piling contractors, but “a concern arises if the client’s not sophisticated enough to understand their environmental obligations,” said Kaufman. “As a contractor, it would be unwise to proceed until you’re satisfied that the environmental concerns and challenges of the project have been identified.”

Certainly, there’s no end to the surprises that can crop up on the job site, as one company had to implement a waste management plan to avoid attracting bears, says Chris Lee, principal with environmental consultants AquaTerra Environmental Ltd. of Vancouver. In that particular case, he said, “they had to step up specific waste management protocols to secure and transfer waste off the site every day.”

Another project resulted in “the confirmation of an archaeological site close to the area, which they had to cordon off as a designated no-go zone.” The site was found as a result of an AIA: Archaeological Impact Assessment, undertaken as a precautionary measure.

Lee is currently working on a project “where we identified an endangered plant species. If it is determined to be within the area of construction, it will have to be moved. We call that ‘translocation,’” he added.

Producing an EMP can be a lengthy undertaking. “It typically involves some fieldwork, background review and determining what receptors exist – fish, mammals or birds, for example – that might be impacted. In some cases, bridge spans or pilings might be in a location where birds are nesting, requiring monitoring and mitigation,” said Lee.

He lists a roster of legislation that must be complied with, such as the Migratory Birds Convention Act, the Wildlife Act, the federal Fisheries Act and the Species at Risk Act…among others. And the regulatory climate is in a constant state of change, necessitating consulting expertise to ensure that compliance is maintained.

“Something becoming more of a central issue is the invasive species management plan.”

Chris Lee, AquaTerra Environment Ltd.

“Certainly the requirements for Project Environmental Assessment have changed over the last few years. The emphasis is to push it away from federal to provincial regulators through changes to the Canadian Environmental Assessment Act that were put through four or five years ago,” said Garth Taylor, vice president and partner with Hatfield Consultants Partnership of North Vancouver.

“In British Columbia – and I think in most provinces – larger projects usually go through a provincial process, and then there are specific conditions where you would either have a joint federal-provincial process or would be overseen by the federal Canadian Environmental Assessment Agency (CEAA),” he said. These would generally be trans-boundary projects, such as linear infrastructure or a bridge across a waterway that is also a jurisdictional border.

The typical EMP table of contents includes a project description plus an assessment of habitats within the project area, and documentation of environmental management (who is responsible for what?), orientation, training and potential environmental impacts.

“And then the meat-and-potatoes is the actual mitigation,” said Lee. “Once you’ve identified impacts – even if they’re perceived as relatively innocuous – you may need to look at developing mitigation strategies.”

These might include “refuelling procedures, concrete management and spill procedures or salvage requirements to remove fish from the work area before construction commences. And then there are usually some ancillary plans that accompany the EMP,” he said. These take in such areas as construction material and equipment management, waste management, spill prevention, emergency response, erosion and sediment control, noise and air quality.

“Something becoming more of a central issue in the overarching EMP is the invasive species management plan; occasionally, there’s also a species-at-risk management plan. It would have to be monitored appropriately,” said Lee. “That leads to the last condition of the EMP: the environmental monitoring and reporting.” If this sounds daunting, it can be outsourced to a specializing firm.

“If there are environmental concerns, we’ll hire an environmental consultant and do an EMP,” said Kaufmann. “There’s always a concern that there may be something we don’t know, so we will outsource our environmental management to a Qualified Environmental Professional (QEP).”

Similarly, Flatiron contracted Spencer Environmental Management Services Ltd. on the Northeast Anthony Henday project to manage the EMP. “The money spent on an environmental company is well worth it, as they’re the experts who know what the government requires for compliance and audit protocols,” said Hodge. “As regulations change and new species come on the protected list – and this project is in the middle of a migratory bird flyway – for a contractor to be knowledgeable of the many regulations and licenses required would require a substantial amount of time and research.”

Practical measures

Many companies practice voluntary environmental measures, such as using biodegradable hydraulic oil or replacing parts that could potentially cause a spill. “We put our hydraulic hoses on a timed rotation,” said Stirling Larwill, health, safety and environment manager for Force Pile Driving. “They’re replaced every 8,000 hours, whether they’re showing signs of wear or not.”

The company also uses Finnish-made Junttan machines. “They are hydraulically driven, so there’s no spewing of diesel. The engines are smaller; they’re compact and efficient. We can put in a pile two-thirds faster than what a diesel hammer can,” Larwill said.

There are several different environmental concerns that contractors can make themselves aware of. “One of the things that people should be aware off is that if your piles have a coating and they have to be ground or sandblasted off, there are fairly strict requirements that you have to follow,” said Kaufmann.

Flatiron pays attention to how long its machines are idling while not in use. “We have a satellite monitoring system that lets us know when a vehicle is moving,” said Hodge. The electronic site monitoring helps reduce carbon footprint, and “we’re able to keep a handle on our costs and eliminate idling vehicles.”

Hatfield Consultants Partnership ensures it minimizes site disturbances at its project locations. “Generally, there’s been a big push to decrease site disturbance, particularly along the banks of sensitive water bodies,” said Taylor. “One interesting thing that has come up – and I think it is now a best practice – is the capping of piles when they’re not in use. In the past, they’ve been accessible to birds, and birds have nested up inside the piles.”

Beyond legislative compliance and the specific measures used in each project, perhaps the most important thing a piling contractor can do is to build a culture of environmental excellence flowing from a corporate environment policy.

“We stress it at the beginning of a person’s employment; at the orientation, we spend a certain amount of time discussing environmental policy,” said Hodge. New employees are quizzed at the end of their orientation, and annual presentations reinforce the learning. “We’re bringing forward the environmental message; we make sure people are engaged all the way through the project.”

Besides employee engagement, “You really need the buy-in from the most senior people in the company that these requirements are accepted, and generally, in my experience working with many clients in the construction industry – not just pile driving – there’s money to be saved by recognizing that regulatory requirements need to be met,” said Taylor. “And by addressing them proactively in the early stages of the project, you can save yourself a lot of time and money later.”