Geopier GeoConcrete® Column System can provide a solution for extremely high loads in very poor soils

By Bentzi Belfon, GeoSolv

Structural foundations are often forgotten by most people outside of the construction industry, even though without those same foundations, most structures would quite literally sink into the ground. As anyone familiar with foundations can attest, they are far from easy to design and can often be very costly, given the many unfavourable surprises you might find underground.

Mark Tigchelaar, president of GeoSolv, a geotechnical design/build firm based in Toronto explains that many of the projects in and around major Canadian cities and towns encounter unfavourable soil conditions that can often threaten the budget and construction schedule of a project. A staggering 80 per cent of work that GeoSolv takes on involves some amount of undocumented fill. Undocumented fill is fill soil placed without records of any compaction effort. As such, there can be little reliance on any real engineering properties to this type of soil, making it difficult to build on.

Many of these fill sites exhibit very low soil strength and contain thick deposits of organic soils, which can be very problematic to the bottom line of a development project. An example of this type of challenging soil profile is the eastern Waterfront of Toronto, also known as the Port Lands, which is reclaimed land. The soil there is a melange of fill including very thick organic zones, placed there starting in the late 19th century.

A traditional method to deal with bad soil is to simply remove it and replace it with good soil. Movement of soil from site to site creates a massive regulatory burden and major time and effort are expended on the details and paperwork related to excess soil management. A major reason piles are chosen for these sites is that it becomes possible to leave the poor soils in place.

As Tigchelaar explains, there have been major gains in the field of ground improvement and there are now solutions available that can easily increase the bearing capacity of even the worst undocumented fill soils by up to five times while leaving poor soils in place and not disturbing them. High bearing capacity offered by these techniques means smaller foundations are needed, thereby lowering overall costs of the project. By stabilizing the existing soils, you can avoid having to completely remove and replace the problem materials, allowing for ease of construction, significant time savings and relief from the regulatory burdens. Also, ground improvement does not require the same structural foundation treatment as piles. With ground improvement, simple spread footings and slab on grade are all that is required.

One of the innovative technologies available to help mitigate these challenges is called the Geopier GeoConcrete® Column System (GCC). GCC elements are used for extremely high loads in very poor soils, such as the waterfront soils described earlier. GCC elements are considered a rigid-inclusion approach to ground improvement. Rigid inclusion solutions are often used for soil stabilization when a load is being transferred through very soft soils to stiffer soil or rock, increasing load carrying capacity and reducing compressibility of the poor soils. Rigid inclusions consist of cement-treated aggregate, grouted aggregate or concreted columns that are used to transfer the stress from the foundation or embankment loads to more competent soil/rock layers. While rigid inclusions can be used as a singular solution for a project, they can also be used in combination with a variety of ground improvement methods to provide an optimized support solution.

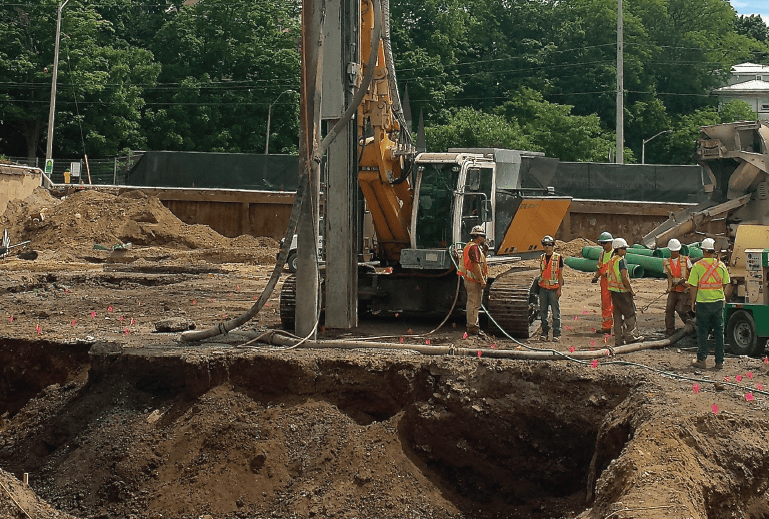

GCC elements use quality-controlled, ready-mix concrete to quickly build expanded base rigid inclusions with very high capacities. A special mandrel pressure vessel is used with a concrete pumping inlet, air valve and gauge, and a stone valve at the bottom end. While pumping in ready-mix concrete, and with the stone valve closed, the vertically ramming mandrel is forced into the ground to the design depth, which is typically a stiff-to-hard layer. The mandrel is then raised and redriven repeatedly with full crowd and vertical ramming energy, extruding an expanded base while improving the base soils below and around the expanded concrete bulb. The mandrel is then pulled up, while extruding a column of concrete right to the surface.

Factors considered during installation include the pressure on the concrete, the pressure in the air gap, the volume of concrete inserted and the rate of mandrel retraction. A load transfer cushion is then placed over groups of GCC elements and a regular spread footing can be designed for high bearing on that load transfer cushion, even in very poor soils. GCC elements can typically treat very poor soils up to depths of 16 metres using 300mm to 500mm diameter elements to obtain very high capacity, while allowing for simplified foundation elements (spread footings at up to 450 kPa SLS) on a load transfer cushion.

Upon first glance, GCC elements appear somewhat similar to belled caissons. While constructed from concrete, there are several aspects of this system that set it in a different class from traditional deep foundations such as caissons (drilled shafts). The GCC elements do not require hard rock or traditional “safe” end-bearing soils like deep foundations do. GCC elements can safely bear onto “good” soils such as medium-dense glacial tills, often found in Ontario, for example, at elevations well above bedrock. These tills are often not considered high-capacity end bearing by expert engineering consultants, and, as such, caissons that are designed to found on tills can often be large and inefficient, with the structural capacity of the caisson shaft far outshining the geotechnical capacity of the caisson at the base on the till; resulting in very large caisson diameters. Therefore, caissons often must extend well into bedrock layers to ensure high capacity and a reasonable diameter.

In contrast, GCC elements are rammed down onto the till soils, improving the till and belling out the GCC element to maximize the geotechnical capacity of the GCC such that the geotechnical capacity at the base is well matched with the structural capacity of the shaft. Further, unlike caissons, the GCC elements are unreinforced, are small diameter and are tightly grouped together. The most striking difference is the ability to design a high capacity footing on GCC elements, through the use of a specially-designed, yet simple, load transfer cushion.