Tekres Group Oy is a family firm in Finland that makes steel components for reinforced pre-cast concrete piles. The company has developed a unique piling system it believes would be a great fit for another northern nation with ample reserves of geothermal energy – Canada.

The CEO and owner of Tekres Group, Jorma Leino, comes from a long line of blacksmiths, that started with his great-grandfather. He also grew up in an area on Finland’s west coast with a rich history of craftsmanship. Inspired by his upbringing and family legacy, Leino studied to become a professional machinist and mechanic, and later purchased a share in his father’s metalworking business, where he looked for new ways to innovate.

Under Leino’s leadership, Tekres Group sought out creative solutions for the deep foundation industry and in 2021, the company unveiled its energy pile – a steel framework for casting reinforced concrete piles that is integrated with an energy system. Leino says he came up with the idea after years of observing piling installation sites. He came to see the ground as “the world’s largest battery” and was struck by the concept that concrete piles could be used as a connector to transfer this energy into buildings.

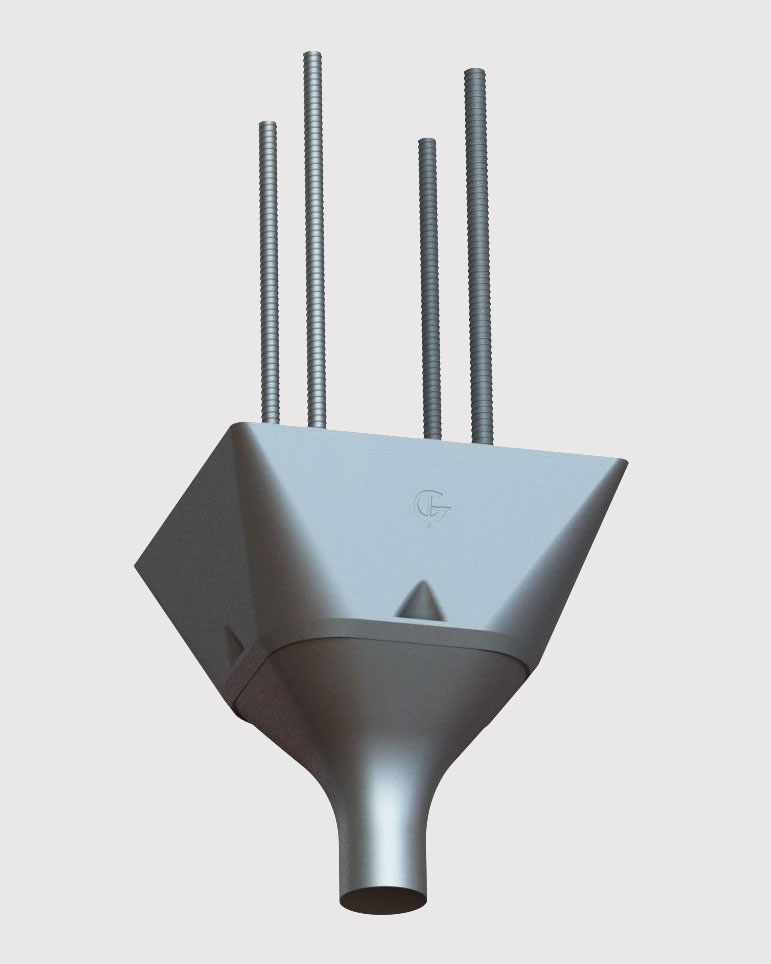

The result is a liquid-based heat exchange system capable of heating and cooling. Here is how the energy pile works. During the manufacturing process, pipes are installed inside steel rebar structures that form the framework for reinforced pre-cast concrete piles. Once the piles are in place and construction is completed, these pipelines are filled with circulating fluid that enables geothermal energy to be transferred up from the ground and into a building’s air conditioning and circulation systems.

The energy piles also help regulate indoor temperatures by serving as heat storage units. “It’s a renewable energy,” said Leino, whose two sons, Kasper and Jalmar also work at the Tekres Group facility in Rauma, Finland. “In the summertime, the piles push heat from the house into the ground, and in the wintertime the energy comes back and heats the house.”

Tekres Group views its energy piles as a cost-effective and eco-friendly solution for end-users looking to lower their electricity bills by reducing heating and cooling costs. According to the company, the piles are compatible with other types of energy systems, such as solar and electric utility power, and can be used for all piling applications where normal reinforced pre-cast concrete piles are used.

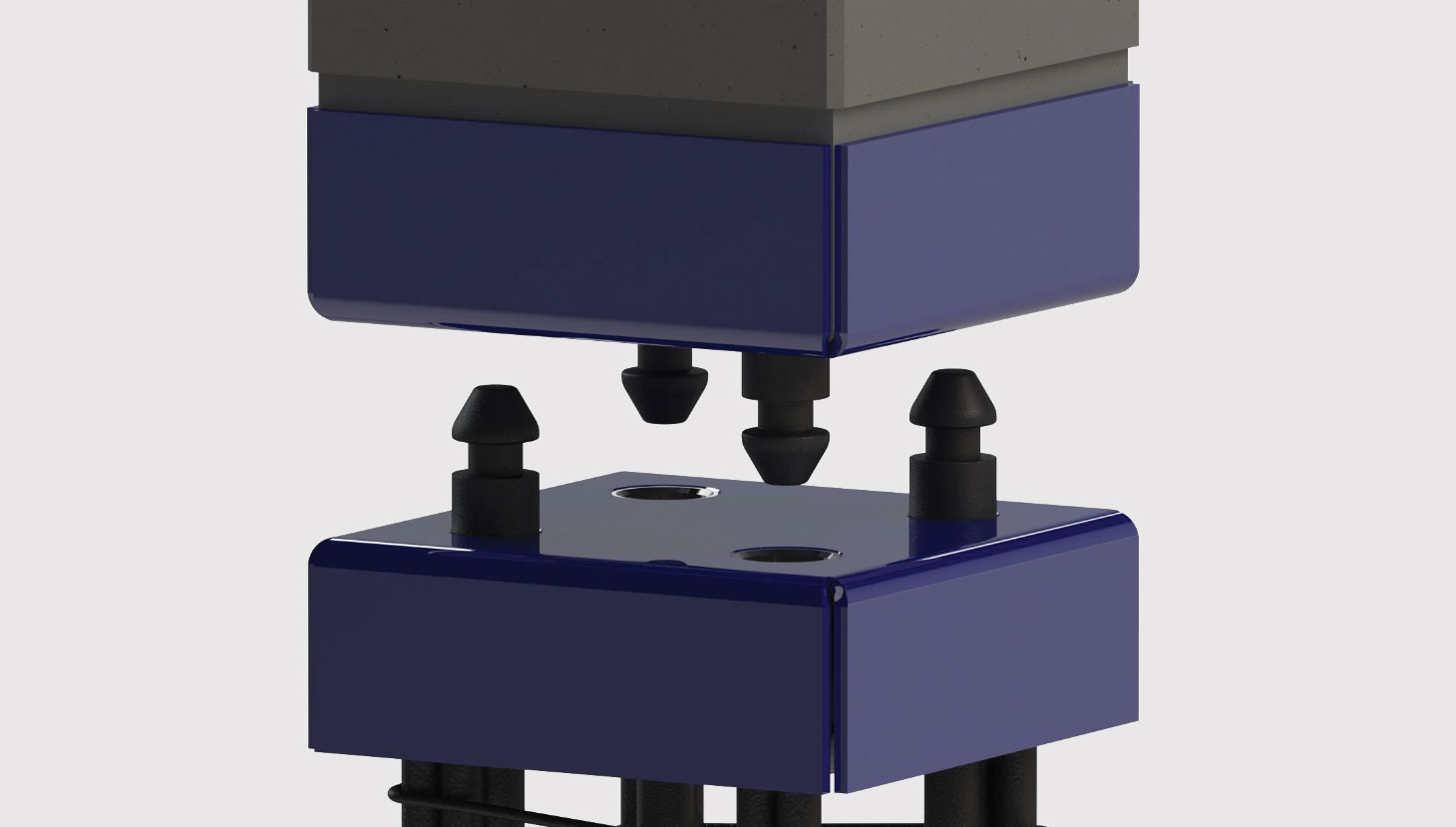

Auto-lock pile joint

Leino’s pursuit of innovation also led to the creation of the auto-lock pile joint, a patented, self-locking and self-tightening steel mechanism for joining different segments of concrete piling. The auto-lock pile joints help to increase efficiency by eliminating the need to weld steel-reinforced concrete piles together on site, which Tekres says not only speeds up the pile driving process, but also enhances workplace safety.

The product enables energy piles or regular concrete piles to be connected and installed at depths of up to 60 or 70 metres deep if needed. According to Leino, this kind of extendable piling system can help streamline construction by saving time and resources. Olli Palvas, the company’s development and sales director, says that the auto-lock pile joint has undergone extensive pile load testing and is certified by the European Technical Assessment agency.

“It’s a renewable energy. In the summertime, the piles push heat from the house into the ground, and in the wintertime the energy comes back and heats the house.”

Jorma Leino, Tekres Group

Another innovation from Tekres Group is its patented rock shoe, a piling attachment that provides additional support for reinforced pre-cast concrete piles when they contact boulders or bedrock during pile driving. The Tekres rock shoe is purported to be lighter and more durable than conventional rock shoes and features a unique cup-like shape that helps prevent pile load slippage and limit pile breakage as well.

Tekres Group’s steel components for reinforced pre-cast concrete piles come in a range of piling diameter sizes from 235 to 350 centimetres. Palvas says the products are manufactured and distributed in a way that not only cuts down on the amount of material needed, but also reduces harmful carbon dioxide emissions.

One example, he says, is how only threaded connections are used in the assembly of the rebar pieces that are part of the Tekres piling joint solution. Palvas explains this enables the rebar and other piling components to be packed tightly together when they are transported to construction sites, reducing freight costs and the environmental footprint of the products.

Both Palvas and Leino are proud of their company and are working hard to expand its reach beyond its native Finland. Palvas says their main market is Scandinavia and elsewhere in Europe, but they also have an eye on the Asian market and have opened an office in Jakarta, Indonesia. He adds Tekres Group is now looking for potential partners interested in producing and distributing its innovative piling products like energy piles in Canada.

“The market is there, and it’s very important to spread the word,” he said.