Concrete is used virtually everywhere in residential, commercial and industrial construction. Rebar reinforcement is used to add structural integrity to concrete to keep it from breaking due to fluctuations in tension, compression, temperature, earthquakes and other stresses.

After a concrete structure is built, it may be necessary to drill or saw into it to incorporate changes. The trouble is that some applications require a significant amount of rebar, which can be set in grid patterns, rows, columns or randomly. This creates a situation where it seems impossible to find an appropriate location to drill or cut without hitting metal. Guessing may result in unnecessary holes, equipment damage and even safety concerns. To mitigate these risks, construction workers require trustworthy metal scanning tools.

The risks of drilling into rebar

A construction site is not a place to take safety risks, but safety is at risk when indiscriminately cutting or drilling into a maze of rebar. When blades or bits hit metal, they can shatter into flying fragments, or grab and bind in the material, causing kickback that can result in severe hand and wrist injuries, if not worse. Worker injuries of this nature can lead to project delays and costly worker’s compensation claims.

A construction site is not a place to take safety risks, but safety is at risk when indiscriminately cutting or drilling into a maze of rebar.

Damaged concrete, drill bits or saw blades additionally lead to downtime and unnecessary replacement costs. It is crucial to identify where rebar is located before drilling or cutting into a concrete structure. One technique is ground penetrating radar (GPR), which can locate metallic and non-metallic objects by sending a small electromagnetic pulse into the concrete and analyzing the echoes that result from subsurface objects.

Although GPR is quite effective at locating rebar deep within a concrete structure, the equipment requires extensive training and can be very expensive. Fortunately, handheld metal detectors have been around for decades and are very easy to use at a lower cost and with fewer headaches than GPR.

Zircon, a sensor technologies manufacturer, offers several models that can detect rebar in concrete at different depths, so the end user can select the best device to fit their needs. In 1980, Zircon introduced the StudSensor stud finder and has continued to innovate in the category for more than 40 years. The Silicon Valley-based, wholly owned subsidiary of ZRCN Inc. produces more than just stud finders. They design and manufacture an extended range of sensor technologies in electronic hand tools including wall scanners, metal detectors, circuit breaker finders, drill guides, water detectors and levelling tools.

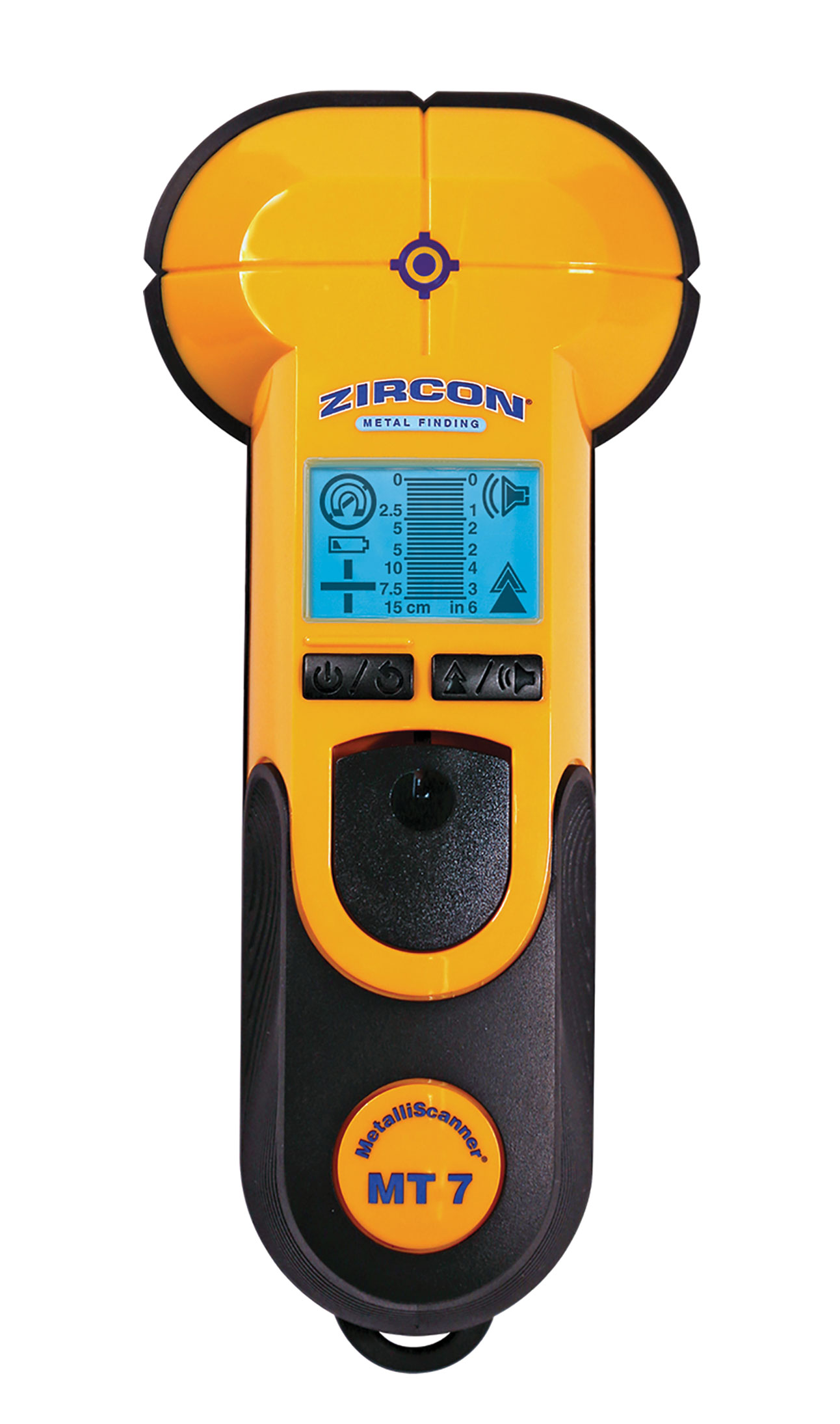

Zircon addresses the issues of locating rebar in concrete through innovative handheld scanning devices such as the MetalliScanner MT 7 and the MetalliScanner MT X metal locators. The MetalliScanner MT 7 metal detector can be used to locate rebar, pipes and other metal before sawing or drilling. The scanner can locate metal, including half-inch rebar, up to six inches deep. It offers users two scanning modes – Standard and DeepScan – with position accuracy to within approximately a half-inch for #4 Rebar, which is often used as a strengthening material in slabs, piers, columns and walls.

The MetalliScanner MT X metal detector is designed to address the difficult task of locating the spaces between rebar in tight grid patterns. In DeepScan mode, the MT X can locate rebar or metal pipes up to four inches deep.

Put to the test in the Devil’s Slide Tunnel project

A Zircon metal scanner was put to the test during the construction of northbound and southbound tunnels for a project along California’s highly trafficked Highway 1, which runs along the cliffs on the Pacific Coast. The area is known as Devil’s Slide due to mudslides from the steep terrain above the highway that often close sections of the road for months at a time. The two tunnels are each approximately 4,200 feet long and are connected by 10 mechanical rooms.

In one of the first phases of the project, the construction crew was tasked with installing a ventilation system in one of the mechanical rooms. However, due to the extensive amount of rebar, the company’s MetalliScanner MT 6 metal detector, the precursor to the new MT 7, was indicating metal “everywhere.”

Zircon addresses the issues of locating rebar in concrete through innovative handheld scanning devices.

The reason there was so much more rebar was its location in earthquake country. One observer described the Devil’s Slide Tunnel as, “less like concrete with steel reinforcement and more like a steel wall with concrete filler.”

Given the challenge, the crew contacted a Zircon representative, who visited the jobsite to help troubleshoot the problem. He suggested that instead of focusing the MT 6 on finding metal, the crew should focus on the weakest signals to find the gaps in the rebar. The team proceeded to use the Zircon MT 6 to scan in this manner in the remaining nine mechanical rooms and were successful in drilling to install the ventilation without hitting rebar 99 per cent of the time – a vast improvement.

The next phase of the project involved installing Jet Fans, which required the crew to drill into concrete while suspended high in a bucket. The MT 6 allowed for quick scans to determine the ideal locations for the 4.5-inch concrete fasteners. The scanner’s lightweight enabled the crew to perform multiple overhead scans quickly. At the project’s completion, the crew advised Zircon that it would be beneficial to add a wrist strap to future metallic scanners to facilitate overhead scanning. This feature has been incorporated in the company’s current model, the MT 7, along with a pivot handle attachment and optional extension pole.

It is crucial to understand where rebar is located before attempting to cut or drill. Handheld rebar detection tools are an easy and cost-effective way to avoid the maze of rebar in an existing structure before a drill or saw ever touches the concrete. For more information about Zircon and its products, call 408-963-4550, email info@zircon.com or visit the company’s website at zircon.com. ![]()