As urbanization accelerates and cities expand, robust foundations are required to withstand geological activities and prevent ground settlement – critical for infrastructure safety and longevity. Consequently, deep piling techniques are crucial for ensuring safety and durability.

Meanwhile, the industry’s focus toward sustainability and site efficiency is driving demand for reliably engineered equipment that minimizes ecological impact, reduces downtime and enhances productivity. This includes the rise of vibro stone columns and worldwide utilization of specialized piling rigs and equipment where traditional deep foundations may be unnecessary, excessive or cost prohibitive.

Global rise

In 2023, the global piling machine market surpassed a valuation of $5 billion and was projected for sturdy growth through 2032. According to Grand View Research, Europe’s market is expected to approach $1.3 billion by the end of the decade – a figure aligned with the U.K.’s goal to build hundreds of thousands of new homes annually from 2020 to 2030. Europe remains the second-largest regional market globally, trailing only Asia-Pacific, with demand being driven by planned investments in infrastructure, alternative energy projects and residential developments.

North America represents a sizable portion – approximately one-fifth – of the global piling machine market, according to Grand View Research analysis, and was projected to surpass $1 billion of the global piling machine market, according to Grand View Research analysis, and is projected to grow at a compound annual growth rate of 4.2% from 2024 to 2030.

Globally, there is an increasing emphasis on efficiency, driven by pressures to minimize downtime on jobsites while enhancing machine reliability and overall performance. This demand is particularly influenced by localized construction requirements and site-specific operational conditions. Worldwide, the piling rigs segment has emerged as the largest revenue-generating category within the piling machine market, accounting for just over 41 per cent of total industry revenue.

A solid basis

Vibro replacement methods – including vibro stone columns – are increasingly applied to accelerate soil consolidation, boost load-carrying capacity and reduce settlement in weaker soils. Particularly useful when up against challenging soil conditions, shallow foundation systems can, in many cases, offer a cost-effective alternative to traditional deep foundations for low- to mid-rise buildings, housing developments and warehouses.

Traditional piles remain indispensable; the new ground improvement technology alone isn’t intended to be a catch-all.

By incorporating stronger granular material into the ground, vibro stone columns help prevent differential settlement, enhance drainage and increase shear strength. They can be enabled without compromising structural integrity, with the potential benefit of reducing over-engineering costs.

Vibro stone column techniques, typically using recycled aggregates and mitigating cement requirements, additionally produce no spoil, bringing down the hard costs of material handling and easing the ancillary side effects of material replacement. Fewer truckloads reduce costs and the project’s carbon footprint. As a result, the new vibro rigs tailored to specific commercial, infrastructure and residential project applications are increasingly seen as vital tools to boosting site efficiency, hitting sustainability targets and keeping transport costs in check.

Piling machine ingenuity: A global fit

Driving piles with vertical vibrations helps reduce soil disturbance and spoil generation, increasing the likelihood of curbing emissions and pollutant runoff. Research from Construction21 additionally highlights how downtime can compound environmental impacts: idling equipment extends project timelines, increases fuel consumption and may intensify habitat degradation.

As sustainable and efficient ground improvement gains priority, global collaborations have intensified around the specialized equipment required for vibro techniques. Reducing ownership costs depends on equipment reliability and downtime mitigation across design, manufacture and service. A recent example of this type of collaboration fueling the innovation is Roger Bullivant Limited and Koppen & Lethem, both in the U.K., and BRADEN, an Arrowhead Winch company, in Tulsa, Okla.

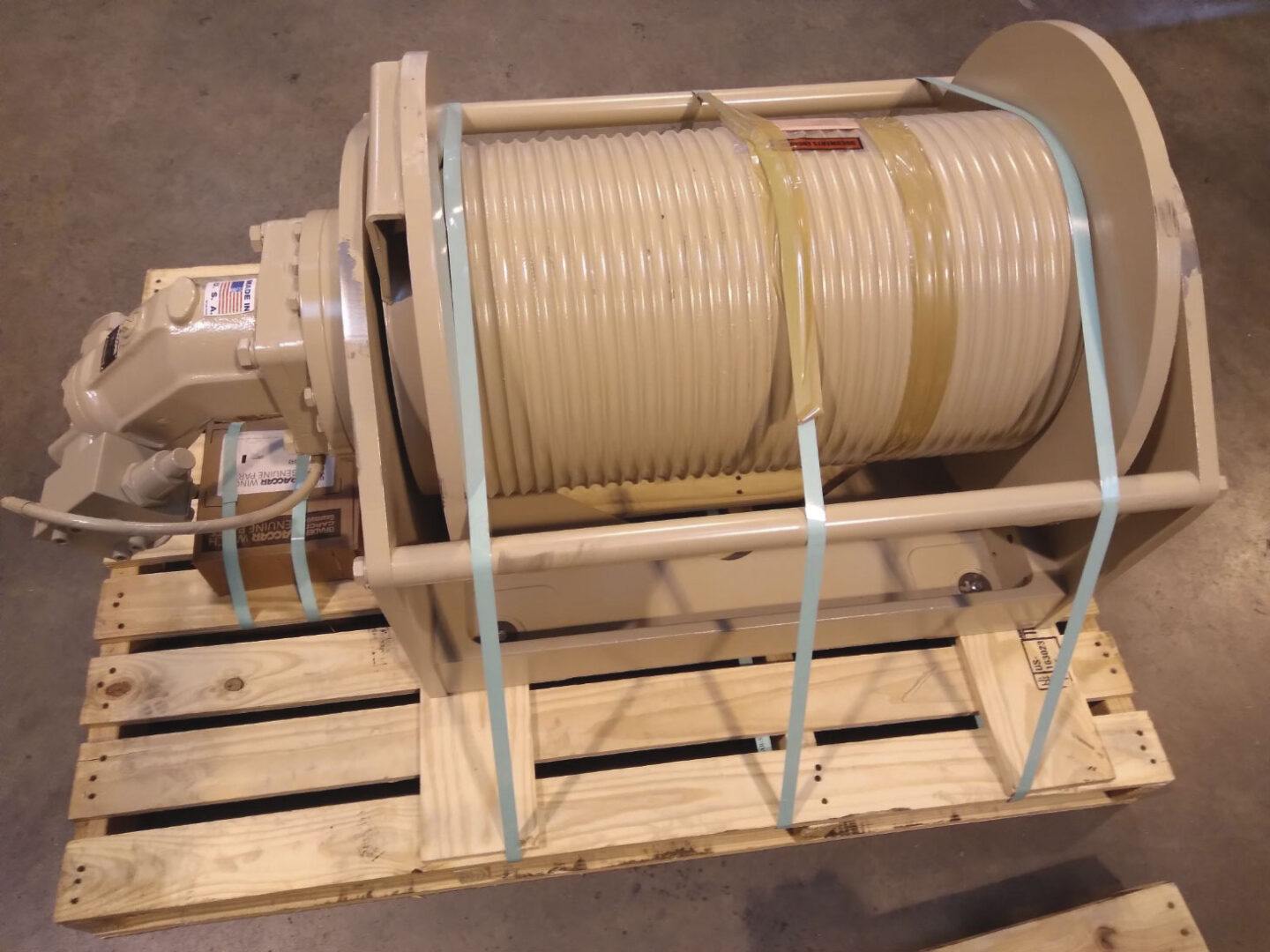

Roger Bullivant Limited, a piling contractor and rig manufacturer, worked with Koppen & Lethem and BRADEN’s engineering team on prototyping and developing a new variation of the CH210A hoist – with a bi-directional “loop system” for driving and extracting vibro stone column probes.

The piling hoist was engineered with a hydraulically released multi-disc brake allowing for greater control over piling equipment. It was designed to ensure precise positioning and consistent operation with cables anchored securely at both ends. The piling contractor and rig manufacturer’s specification works in conjunction with a piston motor that can operate at 300 bar, facilitating increased force.

Designed for higher input RPM, the system boosts productivity, extends service life and supports higher-strength wire ropes. “Piling is a competitive market sector – value for money is crucial,” said Gavin Davies, general manager at Koppen & Lethem. “Designing a loop-style hoist required mounting cables on both drum ends – top and bottom – with the drum grooved for precise rope management.”

Complementing driven piles

Vibro stone columns are increasingly favoured as a cost-effective or complementary solution when facing challenging ground conditions. Traditional piles remain indispensable; the new ground improvement technology alone isn’t intended to be a catch-all. A project’s scope may call for various layouts and application needs are largely dependent on site conditions, project size and owner requirements. In cases where underground obstructions interfere, dynamic compaction – a process of dropping a heavy weight in a pattern – also serves to support densifying in-situ soils and optimizing load-bearing capacities.

Roger Bullivant Limited through multiple projects has demonstrated how various ground improvement methods can be deployed under one umbrella. Recently, they incorporated a multidisciplinary solution to overcome varying geological conditions supporting a low-rise residential development.

To meet all requirements, a three-pronged approach was taken, highlighting compatibility and integrability among vibro replacement methods and traditional piling applications. Top-driven steel tubular piles were used to reduce vibration when close to existing homes. Driven precast concrete piles were installed in a former waste disposal site that was prepared and treated for new construction. Vibro stone columns were leveraged in applicable remediated areas – zones where soil conditions were favourable to incorporating a cost-effective shallow foundation solution. Roger Bullivant Limited used vibro stone columns and displacement piling for foundations at a Walsall housing development on a former residential estate.

At another large-scale housing development, also on the site of a former residential estate, the piling contractor and rig manufacturer used vibro stone columns and displacement piling for the foundations. Their equipment was used to install over 5,000 vibro columns beneath more than 400 housing plots, helping accelerate schedules and lower overall costs.

Global market, competitive growth

Unforeseen downtime can devastate cost and time budgets. The inability to source or locate parts, reliability issues and decision-making vulnerabilities can further impact project timelines. In a competitive market with the potential threat of economic headwinds or geopolitical uncertainty, the path to sustain and grow responsibly may be reimagined through the lens of industry partnerships and supply chains of deep engineering collaboration.

Piling machines show no signs of slowing down amid an increasingly competitive global landscape. The U.S. led the North American segment.

Piling contractors want greater efficiency, better throughput and more velocity, without sacrificing performance, productivity or continuous improvement. Specialized component durability and solution implementation reliability are central to bringing down hard costs associated with idle labour or unanticipated machine downtime, loosening profit margins and bolstering both business and environmental sustainability.

An integrated geotechnical approach may allow for avoiding unnecessary over-engineering while maintaining structural integrity. The broader impacts of rig manufacturers, contractors, hydraulic component specialists and industrial hoist providers are also illustrated – working together to strengthen global partnerships that drive high performance. “Our aim is to solve problems by engineering solutions,” Davies said. “Increasing productivity is king.”