The use of state-of-the-art quality control and assurance (QC/QA) testing technology and tools for deep foundations is very important for maintaining specified standards in construction practices. It has become indispensable, gaining more traction over the last two decades. Specialists are brought onto projects to ensure safe, efficient, reliable and cost-effective testing services for economical deep foundation design and construction.

For more than 50 years, EXP’s team of experts in Brampton, Ont., has provided QC/QA deep foundation monitoring, testing and technology services. These services are essential for measuring geotechnical resistance and assessing structural integrity of deep foundation systems, including driven and drilled shaft piles, particularly for heavy structures such as tunnels, bridges and high-rise buildings. Through extensive experience, EXP has identified the most effective technologies and tools to support its clients’ ultimate goals: successful project completion, on time and within budget.

Technology tools EXP uses to support project success

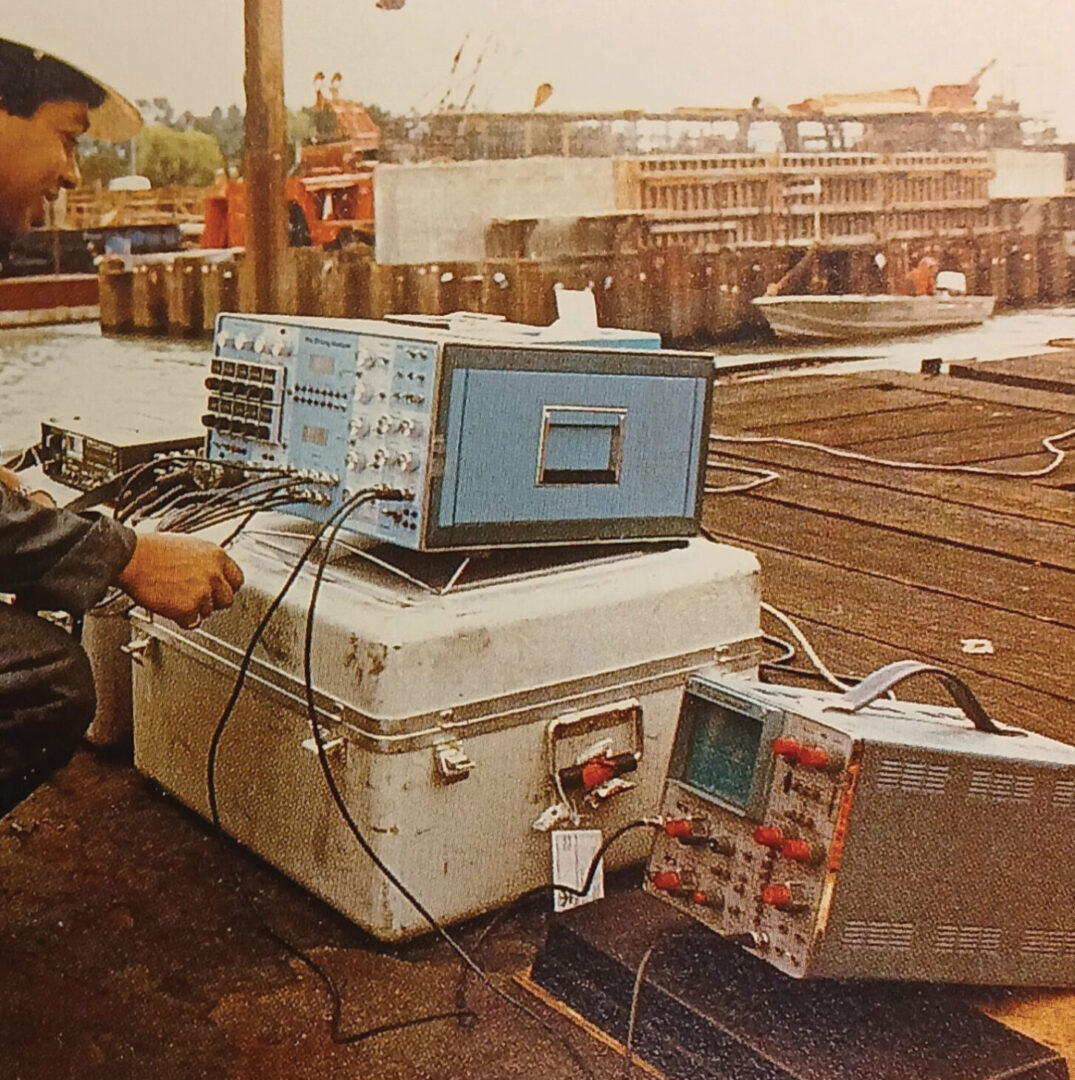

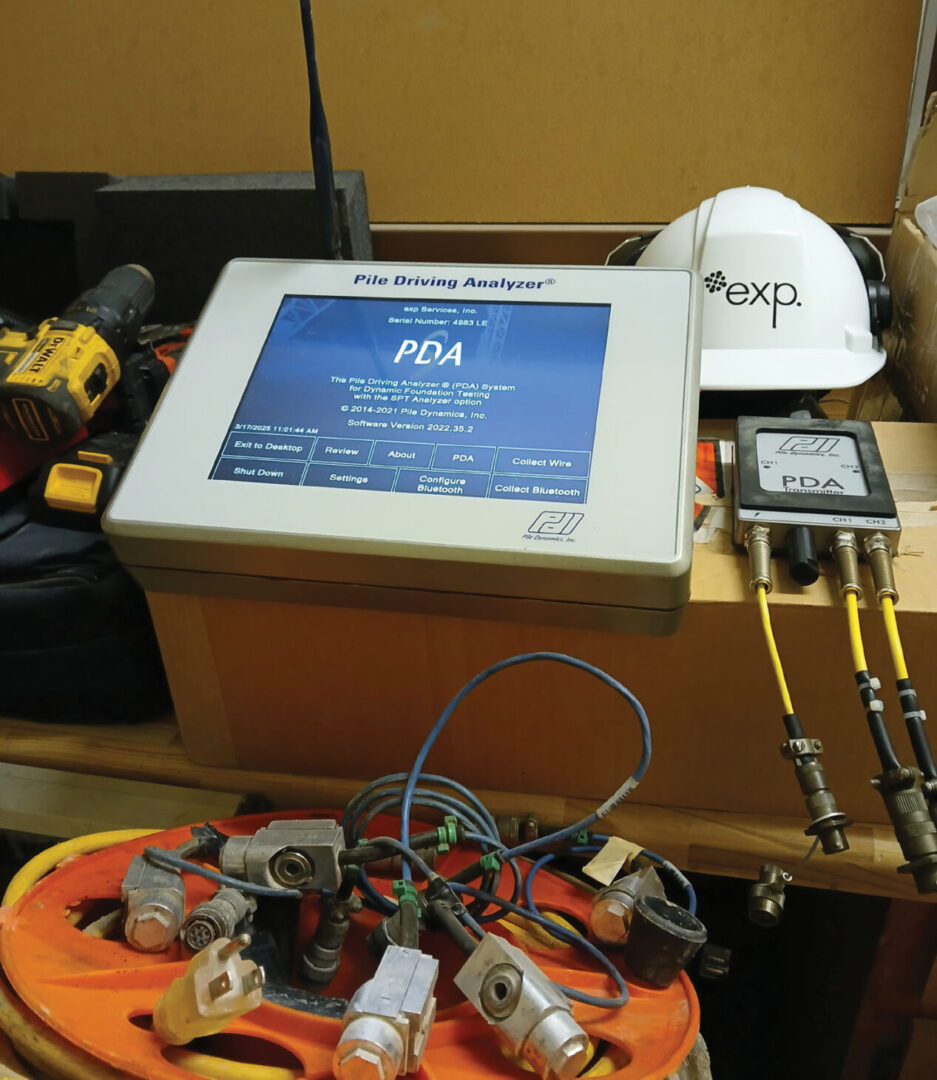

In addition to offering full pile inspection services, EXP is recognized as a pioneer in using cutting-edge, innovative and cost-effective equipment, technology and tools for deep foundations QC/QA testing. With more than 50 years of experience providing wave equation analysis of pile driving (WEAP) software for projects across Canada, the team has completed over 1,500 projects utilizing WEAP analysis and pile driving analyzer (PDA) for high-strain testing.

EXP employs the latest version of WEAP software, which simulates pile response to pile driving equipment, calculates soil resistances, analyzes dynamic pile stresses and estimates capacities based on field-observed blow count for hammer and pile system. The software also assists in selecting appropriate hammers and driving systems according to piling, soil and capacity requirements. It also performs pile drivability analysis and estimates total driving time.

Additionally, EXP has been actively engaged in pile driving monitoring and PDA testing across Canada. The company owns 2018 PDA-8G equipment, which calculates geotechnical pile capacities, assesses integrity and evaluates driving system performance. The system includes Case Pile Wave Equation Program, which processes and analyzes data imported from PDA test results.

EXP also uses the Pile Integrity Tester (PIT) device to assess the structural integrity of concrete piles, and use the SPT Analyzer (SPT-A) to measure the energy transferred into an instrumented SPT rod during a standard penetration testing. Since 2010, these tools have enhanced the accuracy and reliability of QC/QA testing for large-scale construction projects.

As technologies evolve, so does EXP’s team. To help clients stay within scope, budget and timeline, EXP has invested in advanced technologies.

By leveraging high-tech devices, software and testing equipment, EXP ensures cost savings and keeps projects on schedule. The deep foundation team has successfully completed numerous WEAP analyses and testing services, including pile driving monitoring, PDA, PIT and SPT-A testing. Notable projects include WEAP analysis for the Roseville Road underpass at Highway 401, PIT testing for the Albert Street Underpass at Highway 401, PDA testing for the Gordie Howe International Bridge, Highway 427 expansion and the Highway 407 extension. Additional projects include the Canada Drive at Highway 400 Overpass, CN Bridge at Mississauga Road and Highbury Avenue Underpass at Highway 401, among others.

Maintaining the pace of change

As technologies evolve, so does EXP’s team. To help clients stay within scope, budget and timeline, EXP has invested in advanced technologies, expanding its toolbox to include shaft quantitative inspection device (SQUID) – a cutting-edge technology for real-time assessment of the cleanliness and competency of the bottom surface of bored piles or drilled shaft foundations. Additionally, EXP has acquired a cross-hole sonic logging (cross-hole analyzer, CSL) equipment, which plays a significant role in detecting defects in drilled shafts and poured piles.

Market analysis indicates an increasing need for advanced technology and tools that optimize deep foundation design and QC/QA testing. EXP continuously expands its services and is in the process of acquiring the thermal integrity profiler, a tool that evaluates concrete quality inside and outside the reinforcing cage, detecting necking, inclusions, bulges, variations in concrete cover, shaft shape and rebar steel cage alignment. Another coming addition to EXP’s portfolio is the shaft area profile evaluator, a cost-effective device that visually measures a drilled foundation geometry and verticality before concrete pouring, whether in wet or dry conditions. These advancements enable EXP to provide a broader range of QC/QA deep foundation testing services, supporting more projects across Canada.

With respect to applying computer-based solutions to deep foundation problems, EXP’s experienced team has also been using LPILE, APILE, TZPILE and GROUP software for analyzing lateral and axial geotechnical capacity and settlement, simulating load transfer and evaluating response of driven and drilled shaft piles in multi-layered soils.

At EXP, safety and timely completion of testing services are top priorities. Clients rely on the team for required QC/QA tests, analysis and reporting to ensure cost-effective, on-schedule projects. EXP also offers “lunch and learn” sessions for engineers, contractors, consultants and clients to share and transfer knowledge on the latest advancements in deep foundation QA/QC testing. With a deep-rooted history spanning over a century in engineering expertise and services, and a commitment to innovation, EXP remains a trusted leader in QC/QA deep foundation testing and technology services.