On Jan. 1, 2019, Soletanche Bachy Canada Inc. (SB Canada), an amalgamation of two long-standing foundation engineering and construction companies, became one of the country’s largest geotechnical contractors and the North American leader in Soletanche Bachy’s worldwide network of subsidiaries and partners.

Together, Bermingham Foundation Solutions and AGRA Foundations Ltd. hold more than 180 years of experience in geotechnical construction and engineered solutions across North America, including operating as part of the Soletanche Freyssinet Group of Companies for almost a decade.

Established in 1936 in Saskatoon, Sask., originally under the name Western Boring & Foundations, AGRA Foundations built its strong reputation specializing in foundation engineering and construction of deep pile and caisson foundations across Western Canada.

Bermingham Foundation Solutions was established in 1897 – the oldest foundation contractor in Canada – providing contracting services and equipment manufacturing solutions for more than a century. By joining forces, these two companies will bring a huge base of knowledge and expertise to the successful completion of projects, not only in North America, but throughout the world.

“The planning for the amalgamation started in the first half of 2018 at the senior level within North America,” said Robert Marzetti, former president and CEO of Bermingham Foundation Solutions and now CEO of SB Canada. “Consensus in those early discussions was to join forces into a single company and operate across Canada. We talked about how to put the knowledge, expertise and talent of the two companies together and build synergies between them.”

On the first day of Q1 2019, Soletanche Bachy Canada came into existence. National functions such as safety, finance, business development and corporate services report directly to CEO Robert Marzetti, while all operational entities across the country report through the president, Jonathan Hazenberg, formerly president of AGRA Foundations.

The new company will continue to operate out of five Canadian locations: Hamilton, Saskatoon, Edmonton, Calgary and Vancouver. From an operational standpoint, the company is organized along two major geographic divisions: East – VP operations, Todd Barlow; VP project delivery, Andrew Weltz – and West – VP operations, Brian Horner; VP project delivery, Mike Lamborn.

The equipment side of Bermingham Foundation Solutions, Berminghammer, led by Steven England, will continue to operate as a wholly-owned division of SB Canada, manufacturing lead systems, hammers, reverse circulation drills and custom engineered solutions for the pile driving industry out of its 50,000 square foot facility in Hamilton, Ont.

“Bringing together so many years of combined experience in the Canadian market has given us fantastic insight into the soil structures and deep foundation knowledge from coast to coast. Right now, we’re talking about how we can utilize the expertise from one region to strengthen our offering to clients in a different region. An example is, how can we leverage the capabilities out of Ontario, where our marine experience resides right now, to win and execute marine projects in the west?” said Marzetti.

Similarly, the new company is determining how to combine expertise from the Prairies to improve its offering in Ontario. As it continues to grow that knowledge, it will eventually look at expanding to the East Coast. Being part of Soletanche Bachy gives access to expertise and equipment from around the world, which further enhances its Canadian capabilities.

Marzetti sums it all up, “It’s one of those situations where the whole is greater than the sum of the parts.” Two distinguished, long-standing deep foundations companies bringing together all their knowledge and experience into one entity, ready and able to provide a larger offering to all its clients from coast to coast.

Recent SB Canada project changing the face of Toronto’s waterfront

Southeast of the downtown core of Toronto, Ont., lies what is considered to be one of the largest underdeveloped stretches of downtown waterfront in North America – more than 350 hectares of land, much of it stretching along the edge of Lake Ontario. Originally a wetland at the mouth of the Don River, most of the area has been infilled over the past century, blocking and diverting the flow of the river and increasing the risk of flooding in surrounding neighbourhoods.

The Port Lands Flood Protection (PLFP) Project – one of the largest in Toronto’s history – is going to change all that and more. An enormous undertaking, the project is designed to provide flood protection to Toronto’s eastern waterfront and surrounding communities, unlocking almost 300 hectares of land for revitalization.

The project is being led by Waterfront Toronto, the City of Toronto, Toronto and Region Conservation Authority, and CreateTO; and with the support and involvement of Ports Toronto. In June 2017, $1.25 billion in shared funding was announced by the governments of Canada, Ontario and Toronto to deliver the full PLFP Project. Roughly six months later in December 2017, construction began on the Cherry Street Lake filling portion of the project. This early start was thanks to $65 million in tri-government funding through the Clean Water and Wastewater Fund.

Construction began on the full PLFP Project in July 2018 – to be completed in 2024 – involving activities such as the construction of a new one-kilometre-long river channel. Soil contamination remediation and earth-filling operations to raise the grade of the surrounding land will ultimately contribute to the creation of 40 hectares of greenspace and parklands.

Three new bridges, as well as an extension to the existing Lake Shore Boulevard Bridge, will be built; including infrastructure needed to allow for the future development of waterfront neighbourhoods and commercial areas.

Creating new land

The initial component of the project involves reshaping the northwest corner of the Port Lands area around Essroc Quay near the new Cherry Street Bridge. Designed to stabilize the shoreline and to create a new landmass, the project includes constructing a dockwall containment structure and then bringing in a huge amount of locally-sourced fill to create approximately 5,000 square metres of land. This newly created landmass will eventually form part of the future Promontory Park and will also facilitate the re-alignment of Cherry Street and the construction of a new bridge over the Keating Channel.

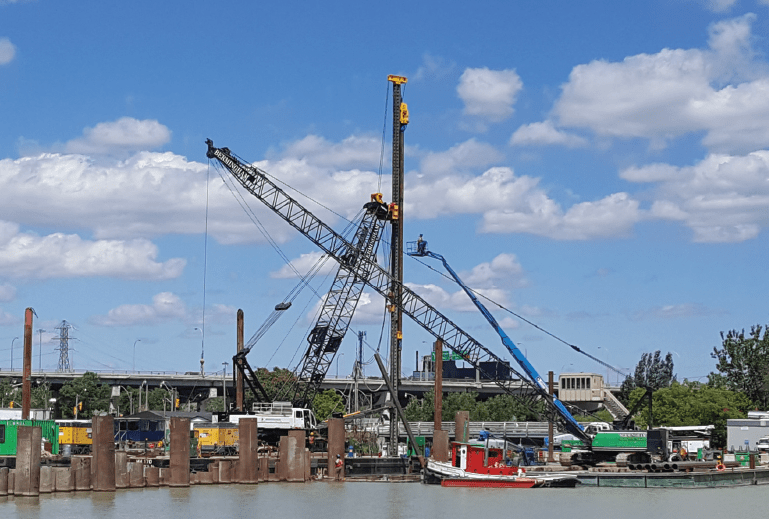

Beginning in May 2018, under the construction management of Ellis Don Civil Ltd., the SB Canada team (then Bermingham), took on the challenge of delivering a marine wall that would form the north and west sides of the landmass containment structure.

“We built a long section of combi wall that ran about 150 metres east-west along the Keating Channel,” said Mike Van Impe, project manager with SB Canada. “Then the combi wall turned southerly and continued for another 45 metres until it tied into an existing quay.”

Van Impe explains that the combi wall was made up of rock socketed hollow pipes laced with sheet piles and tieback rock anchors. Several suppliers delivered these materials: Pipe & Piling Supplies Ltd., a major producer and supplier of steel pipe across North America, and Samuel Roll Form Group, manufacturing steel roll form products for more than 45 years; both provided a steady, reliable source of material.

“One of the more complex things about this project was that rock anchor tiebacks were utilized to ensure plumbness during and after backfilling operations. The rock anchors, which were installed from marine plant, had an outward batter and a socket depth of up to 8.5 metres, and required a massive amount of air to lift the drill spoils. The rock anchor casings were drilled in a single stroke using a down-the-hole hammer and a Berminghammer BHD-40 hydraulic drill mounted to a custom vertical travel lead supported by a 165 tonne crane.

“Contech Systems supplied all the rock anchoring material, and in conjunction with the pipe piles, the sheet piles and the rock anchors, we ended up with a very robust system.”

Bermingham’s internal engineering department designed and manufactured a custom steel template that would ensure the proper location of the wall. The custom template solution utilized the existing dock wall to keep everything aligned.

“We did have a bit of a challenge with an undocumented lake bed depression,” Van Impe said. “Suddenly there was a pocket that fell over two metres, but we solved the problem quickly by splicing additional material to the pipes and sheets. The splicing work was completed both in the field and within our manufacturing plant, and the option to complete the work in two locations greatly reduced the delay and associated costs. It was a ‘field fit’ solution that worked.”

By the end of November, the wall was completed, although working on the edge of a large metropolis, the timeframe could have been much longer. SB Canada deployed two shifts for much of the project which helped Ellis Don and Waterfront Toronto maintain the demanding schedule. Despite some changes and issues along the way, the hard work and responsive nature of SB Canada allowed the project to be completed on schedule. As the backfilling behind the new wall progresses through the winter and spring of 2019, SB Canada will still be involved.

“We are constantly checking the wall to make sure it stays plumb,” said Van Impe. “As the backfilling operations [continue], more and more load is applied to the wall and this causes the wall to bend out. When that happens, we go out and tighten up the anchors to get it back straight and flush again.”

It is this kind of expertise in providing custom solutions, combined with the ability to handle unexpected challenges, that provides the strong foundation beneath the success of the new Soletanche Bachy Canada – for today and into the future.