If you work in the Canadian deep foundations industry, you’ve likely heard Kevin Sharp’s name. Backed by a decades-long legacy in large-diameter foundation drilling, Sharp is a vocal safety advocate. He recently received the 2024 International Association of Foundation Drilling (ADSC)’s President’s Award for his commitment to the success of the association’s 2024 Safety Summit.

Now an account manager with ECA Canada, Sharp relies on his extensive in-field experience to help contractors across Western Canada find the best equipment solutions for their project needs. During a road trip to see clients between Edmonton and Winnipeg, Sharp met up with Piling Canada publisher Jill Harris at a local coffee shop to chat about his career.

When did you start working in the foundation drilling industry?

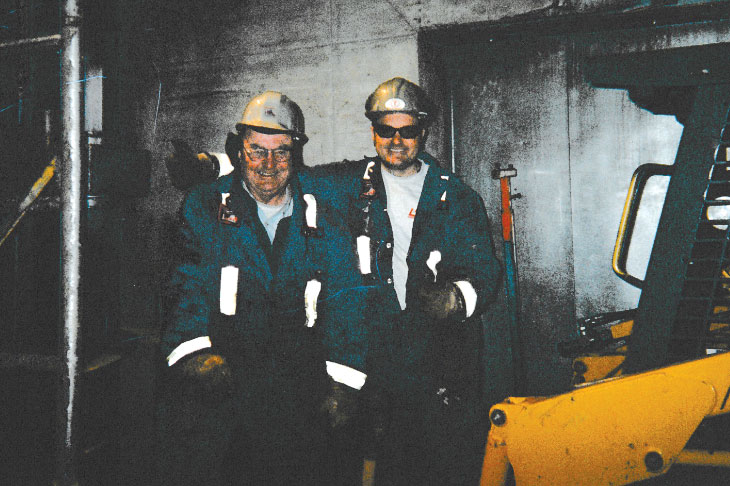

Kevin Sharp (KS): I would say that I was born and raised in the industry. My dad was from Manitoba, but he went to Ontario in the late ’50s to work on the Gardiner Expressway. I was born in North York, Ont., and then we moved back to Winnipeg. I started off working in drilling in Winnipeg in the late ’70s and early ‘80s with my dad at Parkville Caissons. We then moved to Alberta, and I worked for AGRA.

Around 1983, my dad and I started our own company, Sharp’s Construction. In 2006, we were bought by Valard Construction, a powerline company. In 2010, they were bought by Quanta. In 2017, we amalgamated with Northstar. I stayed with them until 2019, as the general manager for Northstar Sharp’s.

And now you’re with ECA Canada. How did that happen?

KS: I left Northstar Sharp’s in 2019. I took three months off, and then I went to work for Western Equipment Solutions out of Salt Lake City, Utah. I was approached by another company that was going to expand into Alberta, and when that expansion didn’t happen, I started with ECA. I’ve been with ECA for three years now.

What are your day-to-day responsibilities as an account manager with ECA Canada?

KS: My territory runs from the Ontario–Manitoba border all the way west to Victoria. I try to see clients – that’s what I like to do. Bauer is our main [equipment] line, so I’m selling Bauer, RTG and KLEMM. We have other lines, too, like HPSI, Digga, Dawson, Pileco – I deal with a lot of different vendors. My territory is big, and I don’t always drive. But [for this trip,] I left Edmonton, stopped in Saskatoon and Regina, then Winnipeg, and now I’ll make my way home. It’s about seven or eight stops.

Do you spend a lot of time on the road?

KS: A fair bit – I would say about 75 per cent of my time is on the road. The rest is paperwork and emails – the stuff I don’t like doing. [laughs]

Which product or equipment line do you enjoy talking about the most?

KS: For me, I would say it’s the [Bauer] BG line because it’s large-diameter drilling, which is basically what I’ve been doing all my life. The nice thing about ECA is that we have subject matter experts on every machine that we sell or rent, and they’re accessible. I’ll call them if I don’t know [an answer to a question]. But I’m comfortable with the technology of large-diameter drilling, so that’s probably my favourite.

What does a good day for you look like?

KS: A good day is when I can go out to the jobsites and see the guys who are actually boots on the ground, being able to see if we can help them in any way. Selling a rig is always a good day, of course, but it’s not like you can sell one every day.

“For young people, you don’t need a degree to succeed in this life. You just have to be loyal, hard-working and surround yourself with positive people.”

Kevin Sharp, ECA Canada

What was it like to transition from the contractor side of the business to the supplier side?

KS: On the contractor side, I liked the challenges of every day – trying to figure out how to put a foundation in the ground and how to estimate it. I do miss that aspect of the job. However, on the sales side, you get to see more people and help them with any of the technical difficulties they might be having on a project. That’s what I like to do. I will help them look at a soil boring and try to give them the best application because when you’ve been around in the industry as long as I have, I’ve probably seen something close to what they’re trying to do … and then they don’t have to learn by the mistakes I [had to learn from].

It must be helpful to have that in-field experience when you’re talking to a contractor about equipment options.

KS: Yes. And when I was on the contracting side, I was always really on top of education and training.

Right now, we’re short skilled operators. I’ve been saying it for 20 years – we need to start building these guys up and making sure that we have workforce development. And here we are, 20 years later – we don’t have [enough] operators.

I want to follow that line of thought, so let’s back up and talk more generally about safety. You’re a staunch safety advocate in this industry. Where does that passion come from?

KS: My Uncle Jack was seriously hurt in a [CFA] accident in 2006. [He lost] one arm at the shoulder, the other at the elbow. For a guy with [his] experience [to have an accident like that], it caused me to think that even though we have these senior guys who know what they’re doing, he just made a fatal mistake that day.

You go on a construction site, and you see a telehandler, you see a skid steer, and those guys – by law – have to have certification to run those. But the guy in a [foundation drill rig] doesn’t need it. It doesn’t make sense.

How have you tried to improve safety throughout your career?

KS: Around 1993, I knew safety was going to be a big deal, so I went through the Alberta Construction Safety Association and got my CSO – construction safety officer. I worked with the National Commission for the Certification of Crane Operators (NCCCO) through the ADSC to build a drill rig operator certification program. It’s the only one in North America that’s ANSI-accredited. But [certification is] not mandatory anywhere other than Toronto, so nobody is jumping on board, which surprises me.

[Editor’s note: Sharp also consulted on the creation of the Foundation Drill Rig Operator Program, offered through the Northern Alberta Institute of Technology (NAIT). This is a nine-module large foundation rig training and a five-module anchor and micropile rig operator training program. While this training is a step in the right direction, this program from NAIT is separate from NCCCO certification.]

Why do you think that is?

KS: Because it’s not mandatory and it’s not recognized by general contractors and owners. If they recognized it and said, “You must be [certified] to come on our sites,” then I can see it gaining popularity. But I’ll tell you that if that’s the reason you do it – just because it’s mandatory – then you’re not doing it for the right reasons. There are companies, like Midwest Caissons out of Edmonton, that all their operators are certified. My son is also in the business – he’s working for a contractor in Victoria, training rig operators. He’s been in the business since he was 17, and he’s 37 now.

“The thing I’m most proud of, or my best attribute, is being a person who people can call.”

Kevin Sharp, ECA Canada

Shafts are getting bigger, so the machines are getting bigger. The Ministry of Labour in Ontario forced the industry to become better after a fatality. I don’t want to go down that road [elsewhere in Canada], but it may take that to wake up the government to [mandate certification]. People need to see that [certification] is advantageous – not only from a safety perspective, but from an efficiency perspective and a production perspective. You’ll see less machine damage with a trained operator, for example. I think we need to just keep working on it as an industry, and we’ll get there. Maybe one day, I’ll still be around when it becomes mandatory.

I will say that with Bauer and ECA, we do more equipment training than any other manufacturer in North America, hands down. We have a caring group and that resonates through the training. It’s another reason why I really like belonging to ECA. They also allow me the versatility to go to ADSC, DFI, PDCA or other groups. I can get involved on safety committees and [initiatives] like that.

Speaking about industry groups, you’ve been involved with the Western Canadian Chapter of ADSC for a long time. Can you tell us about your experience with the chapter?

KS: I started going to ADSC National [meetings] in 1987. I was on the Membership Committee, I always participated in the Safety Committee, and I was on the Board of Directors for a three-year term in the early 2000s. And then we founded the Western Canadian Chapter – Brenda Caron and me. She was with Control Chemicals and is retired now. We really pushed it in 2012. Now, my daughter does all the event planning for [the chapter].

I can’t say enough about our western contractors. They come to events, and out of our five board members, four are contractors. The contractors step up. I did the golf teams last year [for the chapter’s golf tournament], and I was having trouble finding enough vendors to go with the contractors! It was a good problem to have. And I can’t say enough about the vendors and the support we get from the suppliers. Even though we compete day-in and day-out, we’re pretty together when it comes to the ADSC Western Canadian Chapter.

What does it take to maintain good relationships in this business?

KS: For me, doing what I’m doing today – face-to-face meetings. I love hearing their stories about what they’re doing and how busy they are, what their challenges are. And sometimes, our equipment doesn’t fit what [a contractor] is doing, but I still go talk to them just in case they see a [future] opportunity, and they think, “Oh, this guy came and met with me.” I’m probably a pretty lousy salesman [laughs]. I try to be as honest as I can with everybody. But if I’m not selling something they need, and I end up selling them something that’s not going to fit what they’re doing, that’ll be the last piece of equipment I sell that guy. I always tell my boss that I’m a terrible salesman, but they keep me around.

What do you think you’re best known for in the industry?

KS: Just honesty. That’s it. Being able to tell somebody that they can call me, and it doesn’t matter what [their question is] – if I don’t have the answer, I’ll try to find it. It’s always great to get awards and stuff like that, but the thing I’m most proud of, or my best attribute, is being a person who people can call. I could be the guy who says, “I don’t have time for you,” but you know what? You have to make time. Even with my wife and I, we billet junior hockey players. We’ve done it for 13 years. And I’ll tell you, there’s nothing more rewarding than having them invite us to their weddings [years later].

When you look back at your career, what are your biggest wins?

KS: I think that my biggest win would be that I got to work with my family. It wasn’t easy, it was a challenge – but that is my biggest win.

What advice do you have for industry newcomers?

KS: If you work for a company and they don’t have a good safety culture, remove yourself. If they aren’t going to change, get out. Also, obviously every day is not going to be great. Just stay positive – stay full of energy. You’ll have the bad days, but if you stay positive, it’s so much easier. And I wasn’t always that guy. My wife would tell me, “Nobody wants to talk to you before nine in the morning because you’re a bear. Just quit it.” That didn’t really resonate until [closer to the end of my contracting career]. My wife, Juliette, is the most positive person.

But for young people, you don’t need a degree to succeed in this life. You just have to be loyal, hard-working and surround yourself with positive people. And then you’ll be fine.

What are you doing when you aren’t working?

KS: Spending time with my grandkids. I have four – three girls and one boy. I spend time with them and hang out with friends. I should go fishing more often, but I don’t!