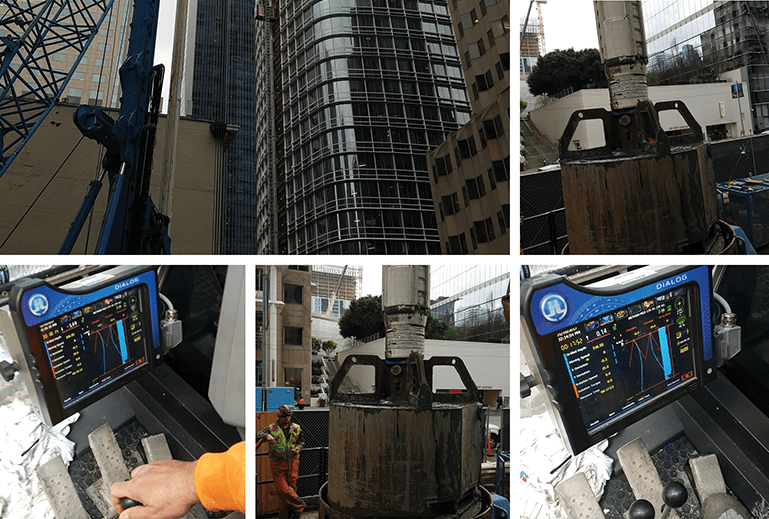

Kelly-drilled piles stay true and on course through the use of Jean Lutz’s PRAD sensor, a user-friendly system that takes immediate readings during the drilling process to ensure accurate verticality control

By Lisa Gordon

As construction moves increasingly into the vertical sphere, the importance of finding new ways to accurately

monitor the quality of a building’s foundation has become abundantly clear.

Back in 2007, Jean Lutz’s headquarters in Jurancon, France, began developing a flexible, user-friendly and cost-effective tool for accurately measuring the angle and calculating the true deviation of Kelly-drilled piles. The French company, founded in 1975, is a world leader in quality assurance monitoring for ground foundations.

By the time Jean Lutz’s North American office opened in Canfield, Ohio, in 2011, the company had launched its PRAD (PRessure And Deviation) sensor, a wireless smart sensor that is attached to the drilling tool.

As it descends into the ground, PRAD’s microprocessor stores data and transmits it back to the accompanying handheld DIALOG display screen, measuring the angle and then calculating the deviation of the hole.

“That’s why it’s called verticality control,” said Michel Lariau, vice president of Jean Lutz North America. “It’s very important to know if you are out of tolerance. When you are building a wall you use several piles, so it’s very important to calculate the overlap between them.”

Lariau has been leading Jean Lutz North America since 2014. The office specializes in four key areas: auger cast, verticality control, jetgrouting and other instrumentation and sensor solutions.

“Verticality control is our number one product,” he said. “The market was always looking for a flexible and easy to use solution. We developed PRAD at a good time when we had wearable technology at a reasonable price.

“Since then, other systems have come to market that allow you to check the verticality of the pile, but they are difficult to operate and very expensive – and they are used after drilling.”

Lariau said the first time Jean Lutz dropped the PRAD sensor into the ground, it knew the device would be a winner.

“The customers were excited by the type of data it produced. It answered our customers’ needs. We were confident because we had so many inquiries about [developing] this type of product, one you can use while drilling. Our product fits perfectly on the drill bit. You don’t need any additional installation. That’s what makes it unique.”

Most of the time, he explained, the PRAD sensor is used to build a secant wall before an excavation.

“If you want to make a foundation, you need to make the location waterproof first. The only way to do that is to make a wall of secant piles to block the water. Once that wall is built, you do the excavation.

“With our system, you will know where you may need to do some remediation work to ensure you are watertight. It’s better to fix this before excavating.”

Not only is the PRAD sensor’s data accurate, but it’s extremely easy to use. In just a half-day, operators can be trained to use the sensor on the drill, as well as to interpret the data it generates.

Since it was released, Jean Lutz has updated the PRAD sensor with an eye to making incremental product improvements.

“In 2011, we made an update for mechanical resistance. Then, there was a second update in 2012 for software and wireless technology,” said Lariau. “Our first concern was improving the accuracy of the system and making it still more user-friendly, in order to take quicker readings.”

In Canada, the PRAD sensor has been used during construction of the Eglinton Crosstown Light Rail Transit line in Toronto, as well as at construction sites in Montréal, Vancouver and Québec City.

Canadian companies interested in testing the equipment can rent a basic system for about US$600 per week, according to Lariau.

Although there is no dealership in Canada, customers can order equipment through Jean Lutz North America’s Ohio location.

From sales to installation and training to technical support, Lariau said the company aims to increase awareness about its products on this side of the Atlantic.

“We want to be considered as a main actor in the North American market.”