I’ve been working on Piling Canada since my very first day at Lester Communications Inc. When I started — three years ago — I had no idea what piling or deep foundations were. If you’d shown me a photo of a jobsite, I would’ve shrugged and said, “construction,” without a second thought.

I was stepping into an entirely new world – one I never imagined would become such a meaningful part of my life. But it didn’t take long before I realized there was something special about this industry. I still remember calling my dad, who lives in Brazil, and excitedly telling him about an article I was editing. He’s a chemist and sales rep for a German company that produces resins used in construction and other industries, and for the first time, I could speak his language – not in formulas or technical specs, but in the stories behind the materials and the people who use them. That moment made it clear to me: this wasn’t just a job; it was a connection, a point of pride.

Since then, I’ve learned not only the terminology and techniques, but also the level of precision, innovation and grit that defines this industry, and I’ve come to genuinely admire the work behind every project we cover.

As you may have read in Lisa Gordon’s article, I’m incredibly proud that Piling Canada is one of the publications helping to document history in the making. The buildings, bridges and infrastructure featured in our pages are meant to stand for decades – and we’re here to tell the stories behind them.

Every project we highlight is carefully chosen by our editorial team with one goal in mind: to ensure it’s relevant, engaging and valuable to our readers. And once those stories are written and published, they become part of our archives – a living record of Canada’s deep foundations industry. That’s why I’m excited to present the 20th anniversary edition of the Unofficial Piling Canada Editor’s Choice Awards, featuring my top 10 most memorable projects:

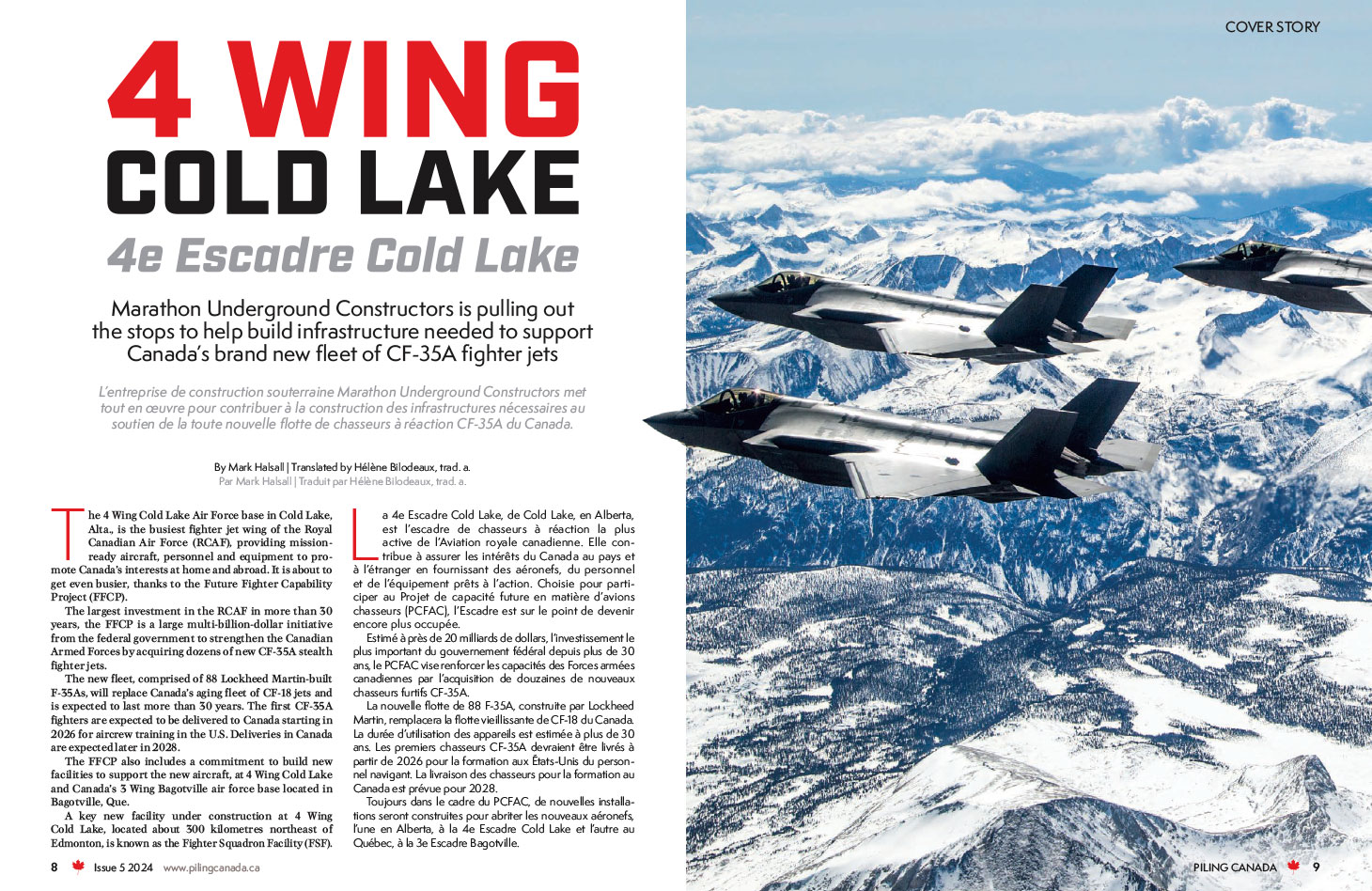

4 Wing Cold Lake

by Mark Halsall – Issue 5 2024, page 8

Why I chose this article:

I still remember when our publisher, Jill Harris, told me we’d be featuring this article in Piling Canada. I had just come back from an extended leave, and she had taken the initiative to reach out to Marathon Underground Constructors about the project. If you’ve ever tried to get past the red tape of a federal – especially military – project, you know how tough it can be. So when we got the green light to share this story, it felt like a small victory. I remember Jill and I waiting for the photos, and we were genuinely so excited when Lockheed Martin gave us permission to use the ones from their gallery. But that’s not the only reason this project earned the top spot on my list.

The deep foundations work at 4 Wing Cold Lake was notable for its complex subsurface conditions, including soft, wet soils and boulders that required heavy-duty drilling equipment and extended drilling times. Environmental challenges, such as groundwater contamination, demanded careful water management and containment strategies. Load testing revealed stronger-than-expected soils, enabling a reduction in pile quantity and delivering significant cost savings. Working on an active military base also introduced strict security protocols. Overall, the project highlighted the importance of adaptability, environmental responsibility and value engineering in deep foundation construction.

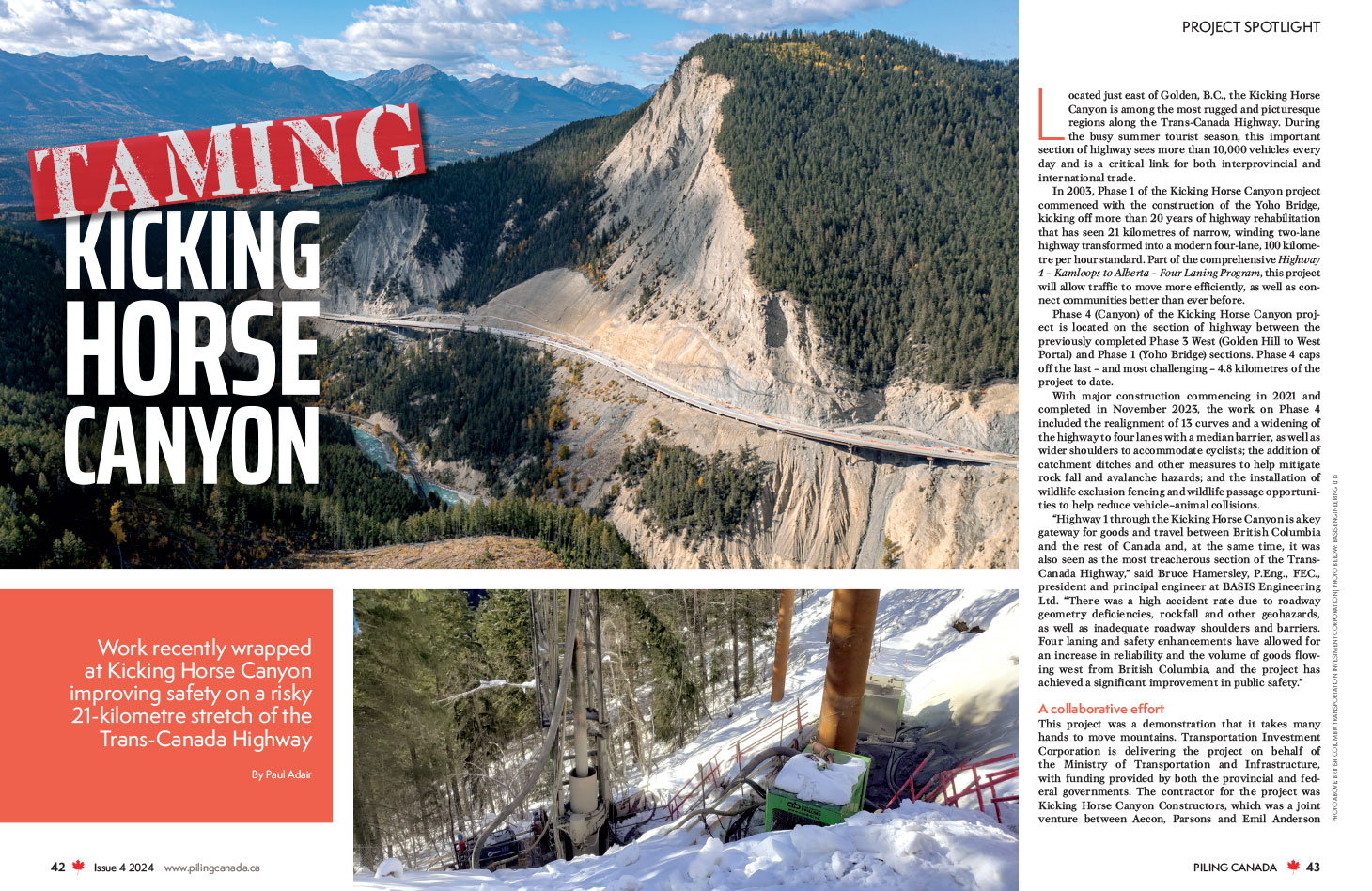

Taming Kicking Hose Canyon

by Paul Adair – Issue 4 2024, page 42

Why I chose this article:

I first learned about the Kicking Horse Canyon project at a presentation I attended at GeoCongress in February 2024. I connected with Bruce Hamersley, president of Basis Engineering Ltd., and we got the ball rolling. This project was quite the engineering challenge – they installed over 500 steel pipe piles, some going as deep as 65 metres, to hold up nine viaducts and three retaining walls. Because the area has steep, unstable slopes and active landslides, the usual foundation methods wouldn’t work. So instead, the engineers designed viaducts that could move with the shifting soil, which helped avoid digging up huge amounts of earth and kept the environmental impact low. They also used high-tech gear like crane-suspended rotary drills and downhole hammers to get the piles in place, even in the hardest-to-reach spots. The project also incorporated environmental considerations by using reverse circulation drilling to control the drill waste and special seals to keep water contained when they first installed the piles.

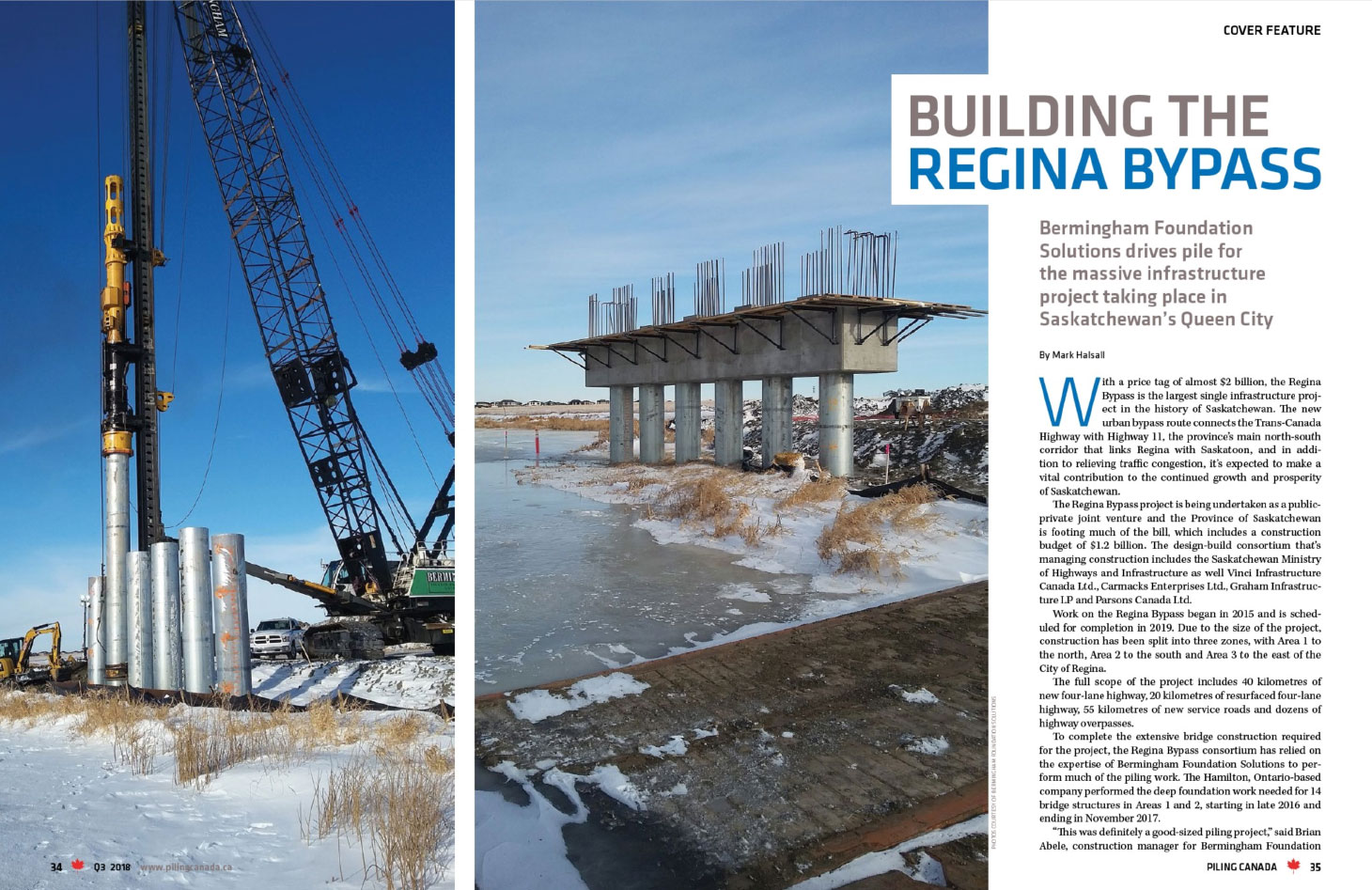

Building The Regina Bypass

by Mark Halsall – Issue 3 2018, page 34

Why I chose this article:

I chose to include the Regina Bypass because it’s a great example of how smart decision-making and adaptability can define the success of a deep foundations project. What stood out to me was how the team pivoted from using drilled caissons to driven piles halfway through – not because of a mistake, but because the geotechnical data and on-the-ground performance supported a more efficient approach. As Saskatchewan’s largest infrastructure endeavour, the project required the installation of approximately 600 piles to support 14 bridge structures across diverse terrains. Initially, eight structures were slated for drilled caissons, but subsequent geotechnical assessments led to a shift toward driven piles for six additional bridges.

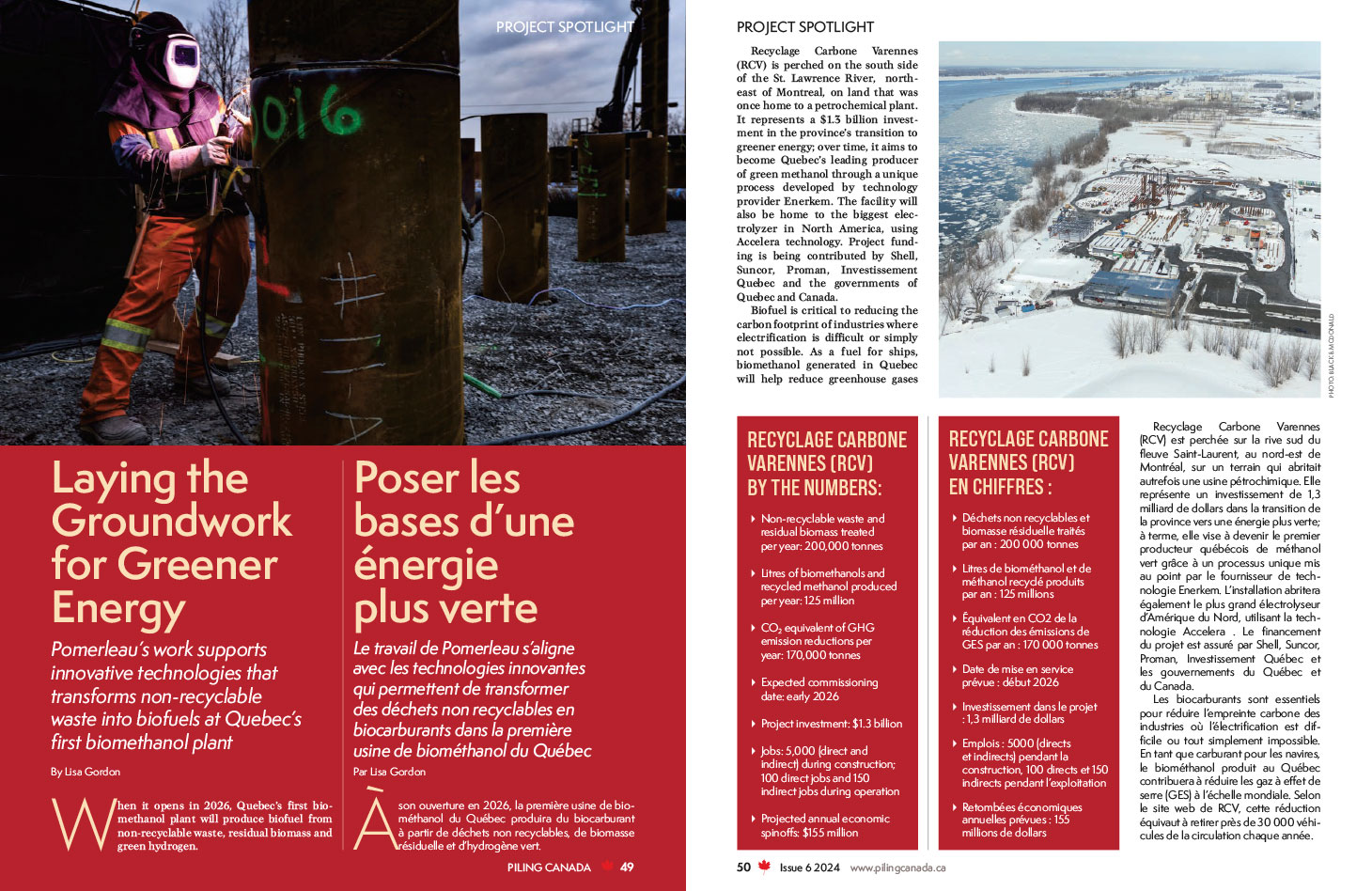

Laying the Groundwork for Greener Energy

by Lisa Gordon – Issue 6 2024, page 49

Why I chose this article:

The Recyclage Carbone Varennes (RCV) in Quebec is a good example of how deep foundations are helping push green energy forward. Set to become the province’s first biomethanol plant, RCV will convert non-recyclable waste, residual biomass and green hydrogen into biofuel, significantly reducing greenhouse gas emissions. Pomerleau was tasked with the deep foundation work and installed 1,800 driven steel piles, some reaching depths of 100 feet to bedrock, over a nine-month period. This massive undertaking involved splicing 3,300 pile sections and managing 17.5 million pounds of steel, all while maintaining high standards for environmental performance and safety. I wanted to add this project to this list because it bridges technical excellence with environmental responsibility. It shows how our industry isn’t just reacting to sustainability goals – it’s helping to build them from the ground up.

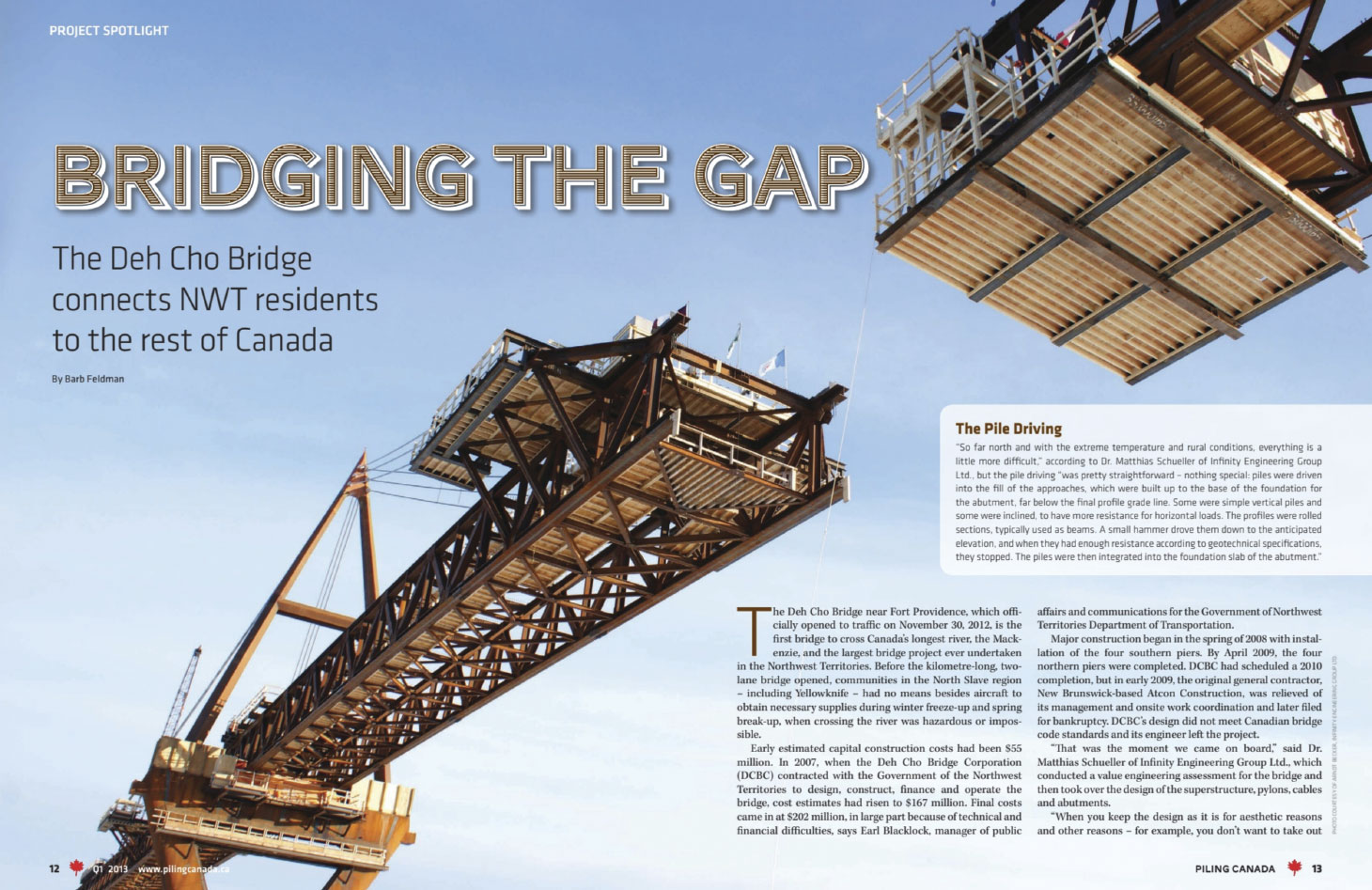

Bridging the Gap

by Barb Feldman – Issue 1 2013, page 12

Why I chose this article:

The Deh Cho Bridge built in 2012 is the longest bridge in Northern Canada, crossing the Mackenzie River near Fort Providence in the Northwest Territories. The bridge is significant infrastructure to the North Slave region, which could only obtain the necessary supplies by air during the winter, when crossing the river was dangerous. Infinity Engineering Group Ltd. (now McElhanney Consulting Services Ltd.) used the Failure-Mechanism-Concept technique to verify the bridge could be built as a single continuous unit with expansion joints only at the abutments. This technique hadn’t been typically used in bridges like the Deh Cho Bridge. Its designers developed a Lego-like system for the assembly-line fabrication.

Cleaning Up the Past for the Future

by Deb Draper – Issue 4 2017, page 12

Why I chose this article:

Bermingham Foundation Solutions (now Soletanche Bachy Canada) installed sheet piling for a massive double-walled enclosure built for the Hamilton Harbour Remedial Action Plan without disturbing the toxic lakebed, which is impressive when you think about the precision required in a marine environment. Riggs Engineering Ltd. developed an engineered containment facility that consisted of double steel sheet pile walls driven into the harbour floor, with the outer wall providing structural support and the inner wall, made of low-permeability Waterloo Barrier® sheet piles, acting as an impermeable barrier. What really stood out to me was how they used a floating template system to guide the piles and kept everything stable without a lot of extra falsework. They even co-ordinated closely with Environment Canada to work around weather risks.

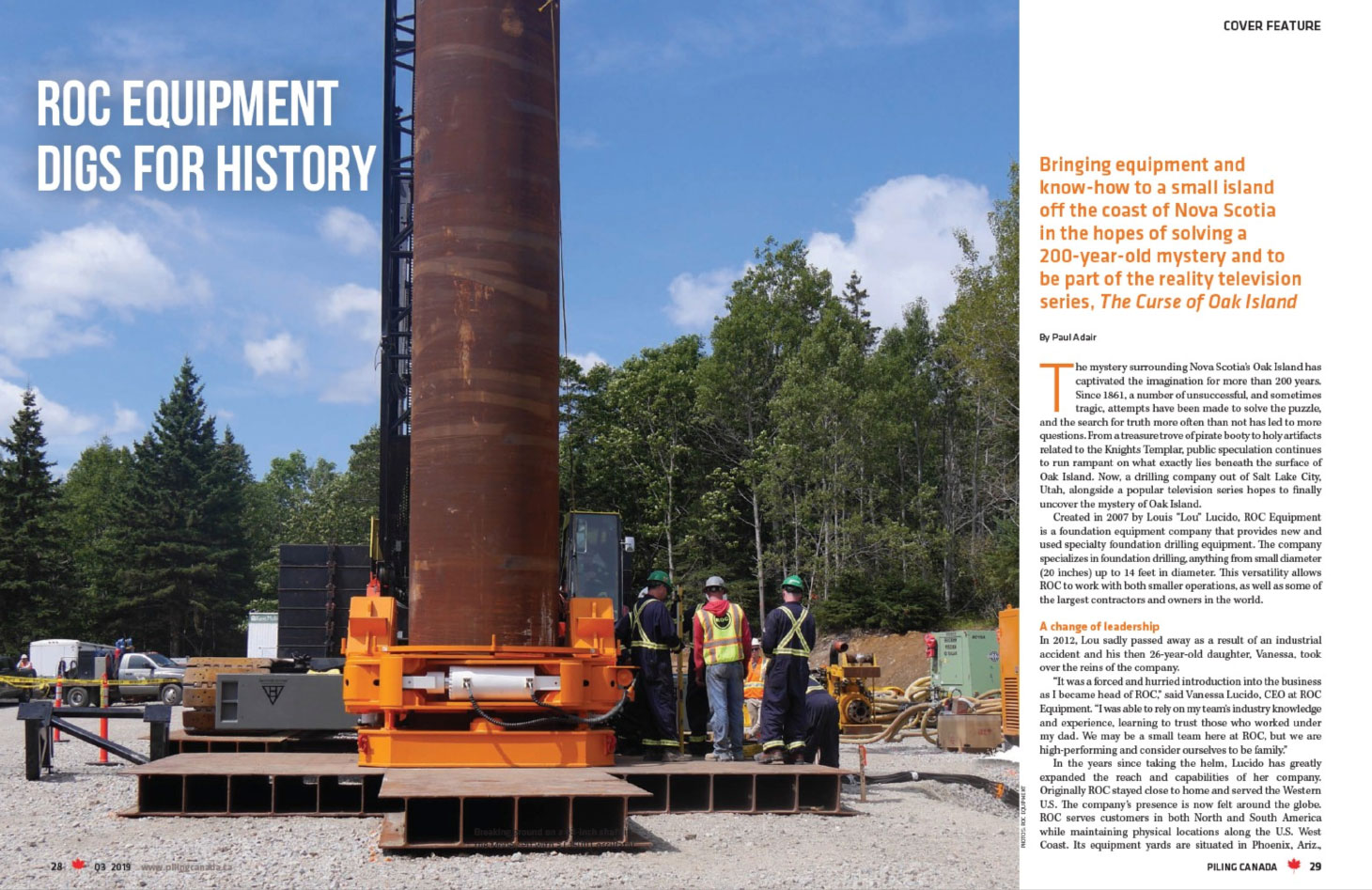

ROC Equipment Digs for History

by Paul Adair – Issue 3 2019, page 28

Why I chose this article:

In 2015, ROC Equipment was summoned to provide its engineering services to help solve the 223-year mystery of what is under Oak Island on the Canadian reality television series, The Curse of Oak Island. What makes this project fascinating from a deep foundations perspective is how ROC adapted its heavy-duty drilling expertise to the unique and unpredictable conditions of a centuries-old treasure hunt. Before signing on, the company conducted exhaustive research into previous attempts on the island to understand what had gone wrong, and to determine whether their equipment was truly up to the task. One key advantage ROC brought to the project was its ability to drill a perfectly straight shaft, something earlier crews struggled with. The project became a showcase of how deep foundations expertise can be adapted to even the most unconventional challenges, like digging for buried treasure.

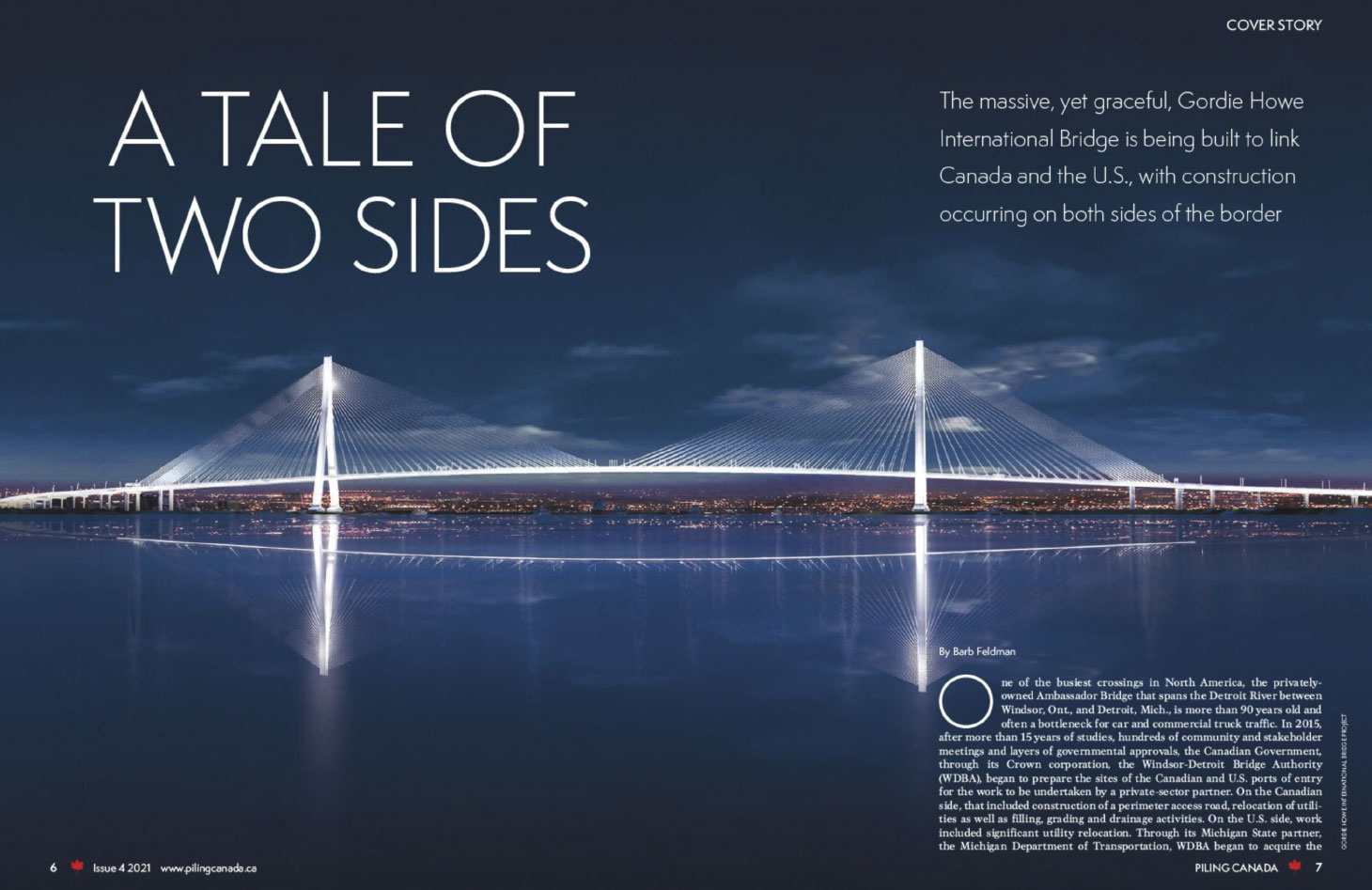

A Tale of Two Sides

by Barb Feldman – Issue 4 2021, page 6

Why I chose this article:

I keep saying that many of the projects we cover in Piling Canada will stand the test of time and are part of history. The Gordie Howe International Bridge project is a reflection of that. The foundation work had to meet a 125-year longevity requirement, undergoing a massive amount of scrutiny, according to Justin Beaveridge, Dragados-Canada’s tower/foundations engineer. All the major components needed full-scale testing to ensure durability and performance. The project involved building a 2.5-kilometre-long cable-stayed bridge – the longest of its kind in North America – spanning the Detroit River to connect Windsor, Ont., and Detroit, Mich. The fact that Canadian and U.S. companies had to work so closely together really shows how complex this project was and just how much co-ordination it took to pull off. Especially now, with some tension between the two countries on trade and policy, it’s refreshing to see this type of collaboration.

Whale Tail Dike

by Olive Taylor – Issue 4 2019, page 45

Why I chose this article:

The Whale Tail Dike project in Nunavut had to overcome extreme environmental and logistical challenges. Henry Foundation Drilling Inc. was tasked with building an 800-metre-long secant pile wall in the middle of Whale Tale Lake, requiring the installation of approximately 1,000 one-metre-diameter piles socketed into bedrock up to 20 metres deep. I chose this project not only for it’s engineering technicality, but also for its commitment to environmental stewardship. The project site required careful ecological considerations since it was located approximately 130 kilometres north of Baker Lake. To protect the lake, double silt curtains were placed upstream and downstream of the work zone, and all fish were relocated from the area. Vibration impacts on fish were also closely monitored.

North America’s Tallest Building on Helical Piles

by Barb Feldman – Issue 1 2020, page 6

Why I chose this article:

I’m amazed by how much helical and micropiles can do. Plus, I love to see pictures of those piles in the ground. Back in 2020, helical piles were still seen by many in the industry as suitable only for light loads. But EBS Geostructural helped flip that narrative with One Richmond Row, a 32-storey high-rise in downtown London, Ont. The site posed a number of serious challenges that ruled out traditional deep foundation methods like driven piles or caissons – driven piles would damage nearby structures due to vibration and caissons meant long construction time, high costs and substantial traffic control plans. Helical piles turned out to be the ideal solution as they could be installed quickly with minimal noise and vibration. It took EBS crews 42 days to install 543 helical piles.