Located in Hamilton Harbour, at the far western end of Lake Ontario, is the Port of Hamilton. The Port is connected to the Great Lakes-St. Lawrence Seaway shipping network. With multiple Seaway-depth berths, the Port of Hamilton, and its sister port, the Port of Oshawa, are able to make marine shipments throughout the Great Lakes and international waters.

The Port and its management have a long history beginning with the Hamilton City Council and the realization that a separate governing body was needed to handle the rapid commercialization and industrial expansion of the Port. In 1912, the Hamilton Harbour Commission was created via an Act of Parliament. Eighty-nine years later, the new Hamilton Port Authority (HPA) took over management of the Port. The Hamilton-Oshawa Port Authority (HOPA), created in 2019, merged the two previous port authorities, HPA and the Oshawa Port Authority, to oversee the economic welfare of Canada along with 16 other port authorities within the country. The Port of Hamilton is responsible for approximately $6 billion in economic activity and provides 38,000 jobs in the province of Ontario.

HOPA owns more than 620 acres of land in Hamilton and is home to a variety of businesses including logistics and transportation businesses for the key regional industries of steel manufacturing, agri-food and construction materials.

The Port of Hamilton houses multiple terminal operations providing storage and transloading of dry bulk and liquid bulk commodities, breakbulk and project cargo. Federal Marine Terminals and QSL are the two stevedores who service the port, and it is also serviced by two Class 1 North American railways: Canadian National and Canadian Pacific Railway Ltd.

The Port of Hamilton is divided between the west and east harbours. Piers 8 to 15 house a large fuel depot and an agri-food cluster on Pier 10, among other facilities in the west harbour. Piers 22 to 29 in the east harbour have multiple agri-food terminals. The port has a grain storage capacity of 100,000 tons, 125 liquid bulk tanks with a capacity of 200,000 tons, 2.5 million square feet of warehouse space, 15 wharves and 8.4 kilometres of St. Lawrence Seaway maximum depth dock walls.

The port handles over 12 million tons of cargo and upwards of 700 vessels each year. It is ranked as the busiest of all Canadian Great Lakes ports. With so much traffic in and out of the port, it is imperative that its facilities are in good condition. The port authority reinvests more than $10 million each year in building and maintaining infrastructure at the Port of Hamilton. These investments ensure that the port is able to meet its mandate of providing efficient transportation and facilitate trade for Ontario industries.

In April 2017, the HPA retained GHD Engineering Services (GHD) of Quebec to conduct a conditional assessment of Pier 12 West. This section of the pier was originally constructed in 1948, using deep arch type sheet piling that was 16 metres long. GHD found the wharf was in very poor condition and beginning to fail. The decision was made to reconstruct the entire west half of the pier in three phases. At this time, GHD also provided HPA with detailed design drawings and tender documents for the reconstruction of the pier.

The maximum loads permitted at Pier 12 had been reduced over time, which limited the use of this important asset. Pier 12 is one of the busiest piers at the Port with over 700,000 tons of cargo handled there each year, including fertilizer, aggregates, salt and steel. The new dock structure is designed for an increased surcharge load capacity of 1,000 pounds per square foot, doubling the original dock’s capacity of 500 pounds per square foot. The new structure is also designed to allow for future maintenance dredging of the adjacent Emerald Street Slip to ensure access by Seaway-draft vessels.

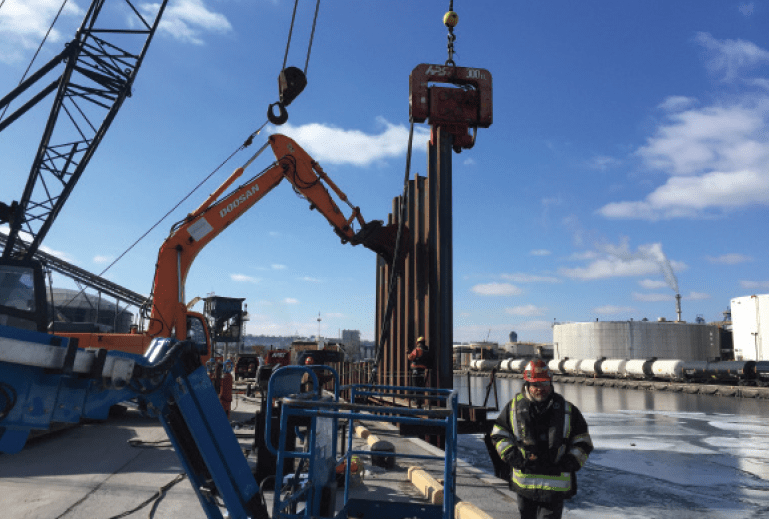

The construction contract for Phase 1 was awarded to Barclay Construction of Ontario and consisted of rebuilding a 208-metre-long section of the southern half of the pier’s west facing wall along the Emerald Street Slip. For Phase 1, HPA pre-purchased the steel sheet piling, AZ 38-700N, from Nucor Skyline. The purpose of the pre-order was to expedite the delivery through the St. Lawrence Seaway before the winter closure.

The AZ 38-700N sheet pile was manufactured in Europe, in partnership with Nucor Skyline, and was shipped via vessel to Sorel, Que., and later trucked to the site at the Port of Hamilton. The AZ 38-700N sheet pile is designed with the Larssen interlock, one of the most watertight interlocks manufactured. The design length of the sheet piles was 19.5 metres to allow for an embedment depth of 9.1 metres. The sheet pile began to arrive in January 2018, and construction of this part of the project was completed within the year.

Phase 2 of the contract was awarded to Dean Construction of Ontario. This phase of the construction involved rebuilding a 168-metre-long section of the northern half of the west facing wall, as well as the western half of the north facing wall of Pier 12. Nucor Skyline was asked by Dean Construction to supply the AZ 38-700N sheet pile for this phase of construction. The sheet pile was also shipped from Europe in the same manner as Phase 1. The sheet pile began to arrive in January 2019, and the sheet pile installation was completed within the year.

The next and last phase of the reconstruction of Pier 12, Phase 3, was also awarded to Dean Construction. This phase began with sheet pile delivery at the end of 2019, and construction was completed in May. In Phase 3, 162 metres of steel sheet pile were driven into place to complete the new reinforcement of Pier 12. Overall, there was a total of 330 metres of new steel sheet pile, walers, anchor piles, tie rods and concrete cope wall between the two phases. Nucor Skyline supplied 131 pairs of 19.8-metre-long AZ 38-700N sheet piles, as well as 131 #20 Grade 80 tie rods for the last two phases of the project.

“Shipments for Phase 3 of the project had to be received prior to the end of the St. Lawrence Seaway’s shipping season. When the Burlington Lift Bridge is lowered for the winter, no marine traffic can get into or out of Hamilton Harbour. Starting Phase 3 on schedule meant having the sheet piling delivered in late 2019 and stored at an adjacent dock. Nucor Skyline facilitated the required offloading, storage and re-handling of the sheet pile to enable a just-in-time style delivery to an already compact site. This permitted finishing work on Phase 2 and preparatory work on Phase 3 to take place unimpeded by the Phase 3 materials,” said Erik Dean, general superintendent, Dean Construction.

The Port of Hamilton sits on reclaimed land that has had mixed use for the last 50 years. The conditions at the site range from loose silt, down to very hard clay till at the tip of the driven sheets. The conditions of the site varied from the west side of the pier to the east side. Dean Construction used the newly purchased 500 HPSI vibratory hammer to take the 17.8- to 19.8-metre-long AZ 38-700N sheet pile down to the design toe of 10 metres into the lakebed.

“Typical driving conditions varied from Pier 12 West to Pier 12 East. However, with the use of the heavy vibratory hammer, no impact hammer was required to achieve proper design toe elevation,” said Justin Soudant, project manager, Dean Construction.

At each phase of construction, the new sheet pile walls were driven within one metre of the existing sheet pile wall. The sheet piles were driven in the first quarter of 2020, with the out of water work being done in the second quarter.