Pile head processing, a critical phase in deep foundation construction, often proves costly and time-consuming for builders.

An innovative mechanical processing method developed by Swiss-based manufacturer BRC Engineering AG offers an alternative to traditional pile head processing, promising lower construction costs, increased quality and shorter completion times while also safeguarding workers and the environment.

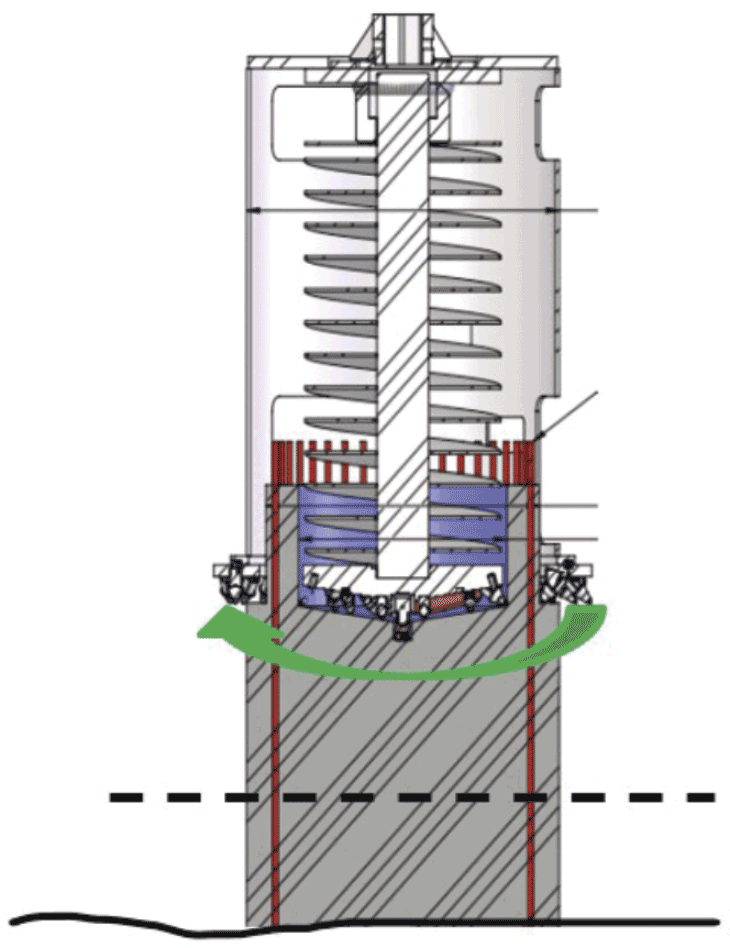

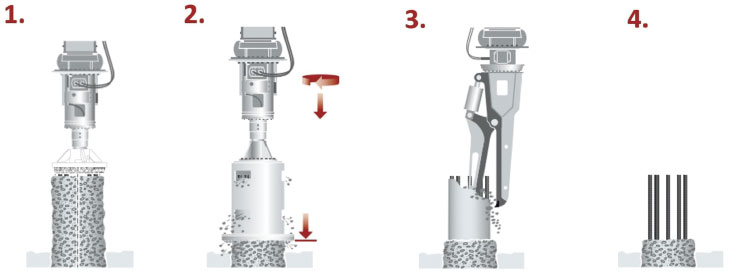

Brextor was designed by BRC Engineering AG CEO Alois Portmann nearly two decades ago to automate the processing of piles for large-scale construction projects. Originally developed for Swiss customers, it is now in use in more than a dozen countries worldwide. Brextor mounts to any excavator boom and uses a hydraulic rotary drive with inner and outer cutters housed in a circular head. These cutters remove excess concrete from the pile head without damaging the piles and can process concrete up to 240 centimetres deep, allowing rebar to extend for integration into the building’s foundation.

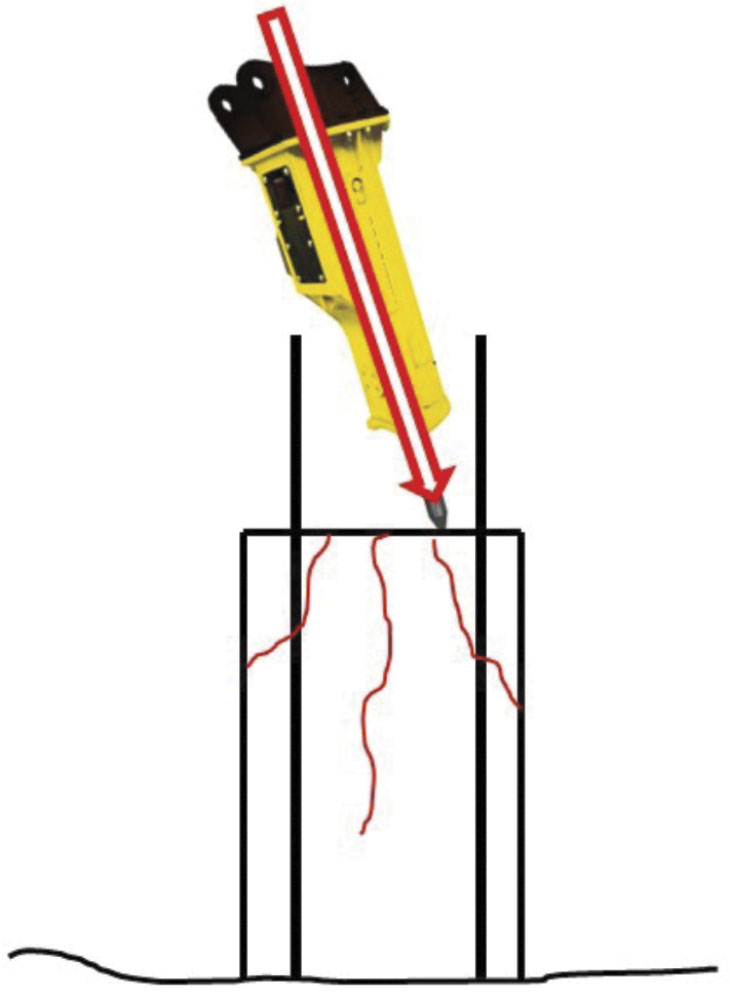

Ali Manouchehri, North American business development partner for BRC Engineering AG, says a tool such as a jackhammer or a chipping gun was usually required to process pile heads, a time-consuming and physically demanding task. The Brextor system can be operated remotely from within the excavator’s cab. This shields the operator from harmful vibrations and reduces the unpredictability associated with manual labour, enabling contractors and subcontractors to more precisely schedule projects.

“With Brextor, you can predict and calculate within a few minutes how long it’s going to take you based on the dimensions and number of piles that you have,” Manouchehri said. “That’s a huge advantage for the general contractor or the subcontractor who is performing this work because they’re capable of predicting and scheduling the entire process of the project.”

Manouchehri also points out that traditional pile head processing can require as many as 10 to 15 labourers, while Brextor generally needs just one operator. This efficiency allows other workers to be deployed elsewhere. Brextor can also process a pile with a one-metre diameter and removal height in just 40 minutes, handling up to 15 piles daily.

Brextor’s innovative milling technology also eliminates the risk of micro-cracks in piles that can be caused by using more conventional tools, such as pneumatic hammers, which can lead to long-term damage to piles and additional repair costs. Brextor also contributes to environmental protection by minimizing material removal. Manual processing typically creates large chunks of concrete that must be transported to a landfill. With Brextor, most processed concrete is milled so finely that it can be reused on the jobsite.

“Because we’re milling down the concrete from the pile, there is very little [solid] concrete left on-site. The part that is being milled down basically becomes gravel … so there is nothing to remove and put on a truck. In most cases, you can reuse it on-site,” he said.

Brextor provides several additional environmental benefits. Eliminating concrete waste that requires off-site transport significantly reduces CO2 emissions. It also produces significantly less noise than conventional tools, and its efficiency reduces the duration of any noise produced, thereby minimizing its impact on workers and residents. Brextor is relatively easy to learn to use. Manouchehri says BRC Engineering AG offers a five-day training course for new operators, allowing them to “hit the ground running” after completing the program.

Brextor has been used on some of the largest and most high-profile infrastructure projects worldwide. One of the most notable projects is HS2, or High Speed 2, a high-speed railway in the U.K. that is being touted as Europe’s largest infrastructure project at present. It is planned as a zero-carbon railway that will eventually connect London with several cities in northern England, including Birmingham and Manchester.

Manouchehri says one of the main reasons Brextor was brought in on the project was its capability to accurately process pile heads in a short period of time, which allowed crews to stick to their schedules. In fact, the system shaved off about 70 per cent of the time that would have been required to complete the task using more traditional tools. “They were blown away with the accuracy of Brextor, and they were very happy with the outcome that they received,” he said.

Project officials were also pleased that labourers who used Brextor weren’t exposed to any vibrations and that there was no damage to the lower portions of the piles installed, as jackhammers were not required for processing.

Another prominent project Brextor was involved in was the construction of a second Gotthard Road Tunnel in Switzerland. The tunnel will allow motorists to travel back and forth between Italy and several countries, including Belgium, Germany, Italy and the Netherlands. Construction is slated to be completed in 2027. Unlike most foundations, in which piles are spaced apart from one another, the tunnel required the construction of a bored pile wall in which each pile installed was connected to the others. The complexity of the project was one of the main reasons Brextor and its ability to deliver highly accurate results were brought in to be part of the project.

“Brextor performed very well despite the overlapping pile configuration. It was very precisely done and the project owners were very happy with it and how it performed,” Manouchehri said. While Brextor is in use throughout Europe and other parts of the world, it has yet to gain significant traction in Canada, where current practices still rely on more conventional pile head processing methods. Manouchehri is hopeful that this will soon change, noting that the Canadian market – facing growing demands for efficient, safe and sustainable construction – has shown interest in Brextor’s capabilities. However, no deals have been finalized.

“With Brextor, you can predict and calculate within a few minutes how long it’s going to take you based on the dimensions and number of piles that you have.”

Ali Manouchehri, BRC Engineering AG

“I would say the Canadian market, with its [focus] on sustainability and labour safety, is very similar to the European market. And with the climate you guys have and with your cold winters, you don’t want to expose your labour to environments where they cannot perform specific kinds of work,” he said. “With all these aspects, I believe that makes the Canadian market, next to the European market, one of the most desirable and important markets for using Brextor. We’re not rushing into anything, but we believe there is much demand for what we have here.”

While Brextor continues to be manufactured in Switzerland, BRC Engineering AG is in negotiations to expand its manufacturing footprint to other parts of the world to speed up access to its product. To that end, it expects to make an announcement soon regarding a partnership with a U.S.-based company.

Interestingly, Brextor was developed by Portmann to address one of the challenges he faced with his own subcontracting construction company at the time: how to speed up pile head processing without putting workers at risk. He joined forces with his brother and came up with Brextor. The finished product was so successful that they decided to begin marketing it to other companies.