Marcus Pipe, a milling facility producing piling-grade steel pipe in Western Canada, is focusing on strategic growth and market expansion.

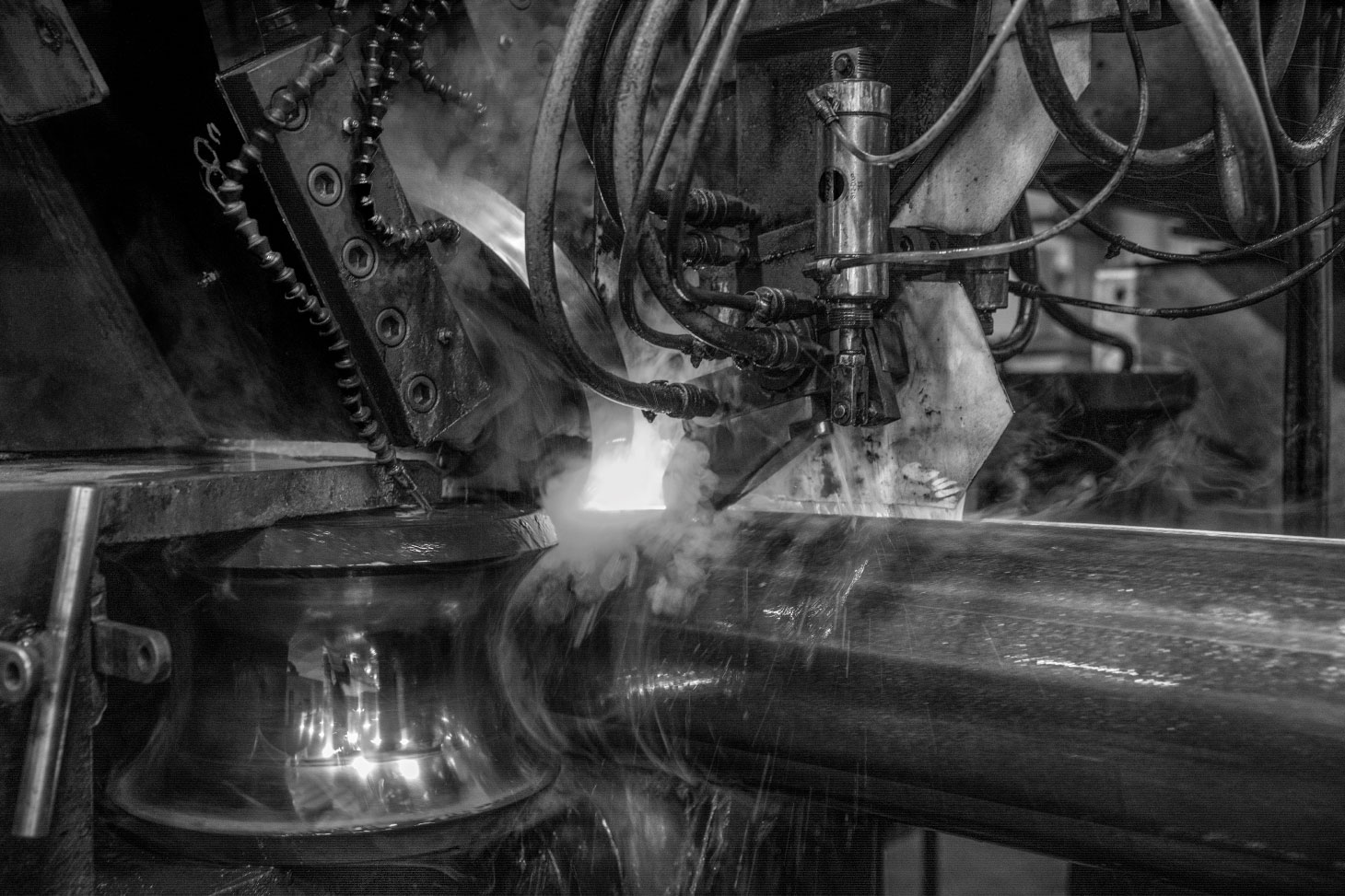

Their manufacturing operations and pipe mill are located in Edmonton, Alta., where the company uses Electronic Resistance Welded (ERT) technology to transform hot-rolled coil steel into ASTM A252 Grade 3 pipe for foundations and structural applications.

Established in 2001, Marcus Pipe will celebrate its 25th anniversary on Oct. 11. Since its inception, its primary customer has been DFI Corporation – a company incorporated in 1969 that has proudly served the industry for more than 55 years, including more than 20 years of manufacturing expertise.

Mike Leakos, director of sales at Marcus Pipe, says his company is now “shifting gears” as it ramps up efforts to increase output at the facility so that it’s closer to reaching its maximum capacity of 150,000 tonnes. An important part of this is attracting new piling customers, not just in the oil and gas industry, but in other sectors.

In addition to driven piles, Marcus Pipe manufactures piling for other deep foundation applications, including helical piles, sheet piles and H-piles. It also produces various structural components specifically designed for piling work. Marcus Pipe also maintains a broad inventory of foundation materials including larger diameter pipe piles, pile caps, backing rings and more. Their goal is to be a one-stop partner for all foundation needs.

The Marcus Pipe mill was designed to rapidly respond to the changing supply needs of piling projects by procuring steel coils well in advance of a project. It is also well positioned to deal with fluctuating market conditions that can hamper project budgets and schedules. The mill boasts a 41,000-square-foot steel processing facility that includes:

- A 20-foot by 70-foot CNC plasma flat steel processing table capable of cutting up to 2.5-inch plate

- A high-output plate press that can precision press plates up to five inches thick

- A CNC pipe profiling and bevelling system

- A 10-station CWB-certified welding facility utilizing SAW, MCAW, FCAW and SMAW processes

- A CNC vertical mill, boring mill and lathe machine shop supporting precision manufacturing of structural components

Leakos maintains the mill’s state-of-the-art technology that allows Marcus Pipe to boost efficiency and meet diverse fabrication needs. An example of that, he says, is how quick equipment changeovers at the mill enable workers to run numerous pile sizes in a short period. The mill produces piles in six standard sizes (5.5, 6.625, 8.625, 10.75, 12.75 and 16 inches in diameter), and wall widths up to a half-inch.

“We can run any length of pipe the customer wants. As long as they can haul it, we can run it. There are no limitations.”

Mike Leakos, Marcus Pipe

Leakos says the company is happy to fill custom-length orders, which saves clients the trouble and expense of having to cut piles to spec on work sites. This also reduces material waste, resulting in better environmental stewardship. “We’re able to manufacture the exact length of the engineering requirements for piling,” he said. “We can run any length of pipe the customer wants. As long as they can haul it, we can run it. There are no limitations.”

Proudly Canadian, Marcus Pipe manufactures high-quality pipe products using 100 per cent North American steel. This commitment ensures reliable supply chain transparency and aligns with the high standards of Canadian infrastructure projects.

Leakos says Marcus Pipe used to buy some of its coil steel from American sources, but that practice ended about four years ago, due to the high U.S. dollar. The EVRAZ steel plant in Regina, Sask., filled most of this gap, with steel plants in Eastern Canada providing the rest. According to Leakos, this reduces transportation costs and enables the company to source high-quality materials swiftly and reduce lead times as a result.

“All our hot-rolled coil is sourced within Canada, which helps us avoid cross-border delays and keeps the entire supply chain Canadian. This not only improves lead times, but also supports the domestic industry and gives our customers added confidence in material traceability and quality,” he said. “Our turnaround time for customer orders is relatively short. This can be anywhere from a day to a few weeks, whereas if you’re ordering materials offshore, you could be waiting months.”

Marcus Pipe also features a 56-acre storage and logistics terminal, capable of holding up to 20,000 tonnes of materials that include hot-rolled coil steel ready for processing and finished pipe products ready to be shipped.

“We always have inventory on hand and we’ve never faced issues with running up short,” said Leakos. “To support large volume and time, our facility includes a rail spur, allowing us to efficiently receive and ship material by rail across Canada and into the U.S. This gives us the flexibility to meet tight project deadlines while keeping freight costs competitive.”